Contents

- 1.1 Introduction

- 1.2 Seeing Red . . . Or Pink, Or Tan

- 1.3 Can’t Judge A Chop By Its Color

- 1.4 The Tale Of Two Patties

- 1.5 The Lesson To Be Learned

- 1.6 References

Originally published as a National Pork Board/ American Meat Science Association Fact Sheet.

Authors:

Melvin Hunt and Becky Zenger, Kansas State University

Reviewer:

Daren Cornforth, Utah State University

Introduction

How would you like your pork chop? Medium rare? Well done? Most consumers have never been faced with this decision. Due to the concern for Trichinella spiralis, typical pork cookery practices involve heating the pork until it is overcooked and white in color. Cookbooks instruct to cook pork until it reaches an internal temperature of 160°F (71°C), which is the medium degree of doneness. Actually, under FDA guidelines, pork can be cooked to 145°F (63°C) for 3 minutes or 150°F (66°C) for 1 minute. Cooking pork at a lower temperature improves the moisture and flavor of the product. The dry, mild flavor that often accompanies pork is due to cooking beyond 160°F (71°C).

But pork must have a white (not pink) color to be safe, right? Many cookbooks say the juices have to run clear to prevent food-borne illness. However, product and juice color are poor indicators of the safety of cooked pork. Pork chops, for instance, can remain pink after reaching the optimal time and temperature combination to ensure safety. Color depends upon which time and temperature combination identified by the FDA Food Code is used. Chops that are pale, soft and exudative (PSE) or dark, firm and dry (DFD) also will have different cooked color. Ground pork patties, on the other hand, may exhibit the same premature browning that has been observed in beef patties (Hague et al, 1994). Premature browning in ground beef occurs when the interior color is brown, indicative of thorough cooking, but the internal temperature is lower than that needed to kill pathogenic bacteria. Thus, premature browning is of concern from a food safety standpoint. The lesson derived from this combination of findings is to use a meat thermometer—judging meat doneness by appearance alone is risky business and almost guarantees less than optimum eating quality.

Seeing Red . . . Or Pink, Or Tan

Myoglobin, the red, watersoluble protein in muscle, is responsible for the pink/ red color of muscle foods. Although hemoglobin often comes to mind when thinking about red color in meat, myoglobin plays a much more significant role in meat color. Different forms of myoglobin produce different colors, resulting in purple (deoxymyoglobin), red (oxymyoglobin), and brown (metmyoglobin) meat. The chemical reactions of oxygenation and oxidation-reduction produce the three forms, which lead to the change in color as meat is exposed to heat. These changes in color in beef products have been identified for years and are frequently used by consumers and chefs for doneness judgments. The typical doneness levels of beef (rare, medium rare, medium, and well) are evaluated by cooked color (AMSA, 1995). Such guidelines have not been established in pork products. While beef follows a red to pink to brown pattern as it is heated, pork turns from pinkish-red to less pink to tan or white.

Myoglobin concentration in beef is greater than in pork. Consequently, the forms of myoglobin are easier to identify in beef, while the color changes in pork (red, purple and brown) are more subtle. Muscle pH and quality are factors that have large effects on cooked meat color. Pale, soft and exudative (PSE) meat, which results from a rapid decline in pH, makes the myoglobin more heat liable and leads to premature browning in cooked product. Conversely, dark, firm and dry (DFD) meat has a higher pH, which protects the myoglobin and keeps the meat pink for a longer time than usual.

Due to myoglobin form differences, ground pork is not expected to have the same color as whole muscle pork (e.g., pork chops). The center of chops and roasts are not exposed to oxygen and are purplish-pink. The anaerobic condition causes the myoglobin to respond to heat in a reliable manner and change from pink to less pink to tannish white when cooked. For ground products, however, all three forms of myoglobin may be present because conditions are more aerobic These three forms react differently to the heat, causing inconsistent cooked color in ground product. In beef, oxymyoglobin and metmyoglobin turn brown readily when heated, leading to premature browning (Hunt et al., 1999). Deoxymyoglobin is more resistant to heat and changes color in a predictable manner from red to pink to brown when heated. The pigment form in the center of the ground product is critical to the color observed after cooking. For instance, if the product begins with a brown interior color, the interior will be brown after cooking. If the product is bright pink in the center, premature browning is possible. But, if the product begins with a purple-pink center, the product will progress from red to pink to tan, just like the chops.

Premature browning is a more serious concern in ground pork products than chops and other whole-muscle cuts. Chops are only susceptible to surface contamination. Therefore, identifying cooked color trends in chops is a product quality concern, not a concern of safety. In ground pork, however, premature browning can result in a patty appearing to be safe when bacteria may still survive.

Although cooked color in pork is already complicated enough to frustrate most processors and consumers, the myoglobin in meat can further complicate the situation. Intact and ground meat can display two other characteristics known as persistent pink color and return-to-redness (Cornforth 1994). These phenomena are characterized by an unusual degree of pinkness relative to the endpoint temperature.

The persistent pink color is principally related to high pH conditions that stabilize myoglobin to heat (Mendenhall 1989; Trout 1989). Consequently, the pigment that has not been fully denatured during cooking will appear pink, and when exposed to air, it can become brighter pink due to the formation of oxymyoglobin. There are numerous factors that affect persistent pinkness; however, most often the culprits are a higher than normal muscle pH and myoglobin predominately in the deoxymyoglobin form. Pork with a pH 6.3 or higher almost always results in pink coloration even at well-done temperature. However, persistent pink color can start to appear at pH 6.0, especially if deoxymyoglobin is present in the meat. This pigment form must be heated to a higher temperature for browning and denaturation than oxy- or metmyoglobin.

The return-to-redness phenomenon (a condition separate from persistent pinking) can occur in wellcooked, vacuum packaged meats during distribution and storage (Cornforth, 1991). The brown pigment (denatured globin hemichrome) is slowly reduced to the pink or red denatured globin hemochrome under anaerobic conditions. Consequently, the meat will appear tan or brown when cooked but it will be pink to red when sliced by the consumer. In this case, return-to-redness is not a food safety issue because the meat was thoroughly cooked. However, return-to-redness (also called color reversion) has been associated with microbial growth and spoilage of ground beef (Faustman et al., 1990) and to minimally cooked bratwurst (Ghorpade et al., 1992) due to microbial reduction of brown metmyoglobin to purple deoxymyoglobin and red oxymyoglobin.

While the different shades of cooked beef color have been studied and are used by chefs and consumers, cooked pork color has not received the same attention. This contributes to the overcooking of pork and poor consumer responses. To help elucidate the problem, researchers at Kansas State University explored cooked color in pork using FDA-approved endpoint temperatures and recorded the differences in color caused by muscle quality, muscle pH, myoglobin forms and product packaging. From these findings, two cooked color guides were developed that show the shades of color that pork can display when it reaches a safe endpoint temperature. These guides (Hawthorne et al.) are designed to help consumers and the food industry properly prepare pork to assure paramount product quality and safety.

Can’t Judge A Chop By Its Color

Muscle pH and product quality affect the cooked appearance of pork chops (Lien et al., 2002a). In the KState research, raw chops that were PSE had an average pH of 5.2, as compared to pH 5.6 for normal pork. DFD chops had a higher than normal pH with an average of 6.6. Normal quality loins that were injected with a quality-enhancing marinade had a pH of 5.6. As expected, raw DFD meat was significantly darker than normal meat with or without injection of tenderness and flavor enhancing marinates. The PSE loin chops were significantly lighter than normal and normal-injected pork. Raw DFD chops also had significantly lower a* (redness) and b* (yellowness) values than normal, normal-injected or PSE meat.

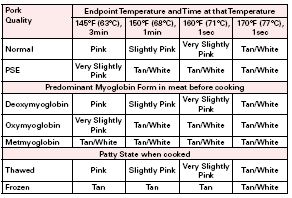

How do these raw meat properties translate into cooked meat appearance? This research (See the Pork Chop Cooked Color Guide) found no visual difference between normal, normal-injected, and PSE at temperatures at 145° (63°) and 150°F (66°C). At 160°F (71°C), the normal and normal-injected chops were slightly pink, but the PSE chops were no longer pink (Table 1). DFD chops were pinker than other chops at each of the endpoint temperatures. Cooked DFD meat also had higher redness (a*) and yellowness (b*) values than the other three groups. In fact, the DFD chops were still pink at 170°F (77°C) and only at the highest endpoint temperature (180°F or 82°C) did they lose pinkness (photo not shown in the color guide).

PSE and DFD chops produce different meat color when cooked to the same temperature as normal or normal- injected pork. Enhancing the quality of the meat through injection did not affect raw or cooked meat color. However, if enhancing solutions raise the pH, the product may be more pink than normal. Since cooked meat color is affected by meat pH, appearance alone cannot be used to determine meat doneness. Pork is juicier and more flavorful when not overcooked. An awareness of the differences in uncooked pork color can increase consumer satisfaction with pork products.

The Tale Of Two Patties

Color is not a good indicator of doneness of either ground pork or beef. Usually, the inaccuracy is associated with premature browning rather than with persistent pinking. Patties with premature browning could have food safety ramifications since the product would appear more fully cooked than is actually the case. Meat quality factors, packaging and cooking techniques make a noticeable difference in the cooked appearance of pork patties (see Ground Pork Cooked Color Guide).

The form of myoglobin found in the patty meat at the time of cooking also has an affect on cooked internal color (Lien et al., 2002b). A significant difference was found in the visual scores of patties at the lower endpoint temperatures, depending on whether they contained deoxymyoglobin, which has a purple-pink color typical of that in vacuum packaged pork, or oxymyoglobin, which has a bright pink-red color typical of that in tray-packed retail pork. Meat containing mainly deoxymyoglobin progressed from pink to tan at each endpoint temperature (Table 2), while meat containing mainly oxymyoglobin appeared tan from 145°F (63°C) to 180°F (82°C). These observations highlight the fact that meat with high levels of deoxymyoglobin can result in pink patties after cooking, even though the product may have reached the acceptable endpoint temperature of 145°F (63°C) for three minutes. On the other hand, patties that were more bright-pink (oxymyoglobin) had a more tan internal color after cooking, and a thermometer was needed to accurately delineate the degree of doneness.

K-State research found that patties made with PSE pork appeared more well done that patties made with normal meat. PSE patties had significantly less pink color, particularly at the lower endpoint temperatures of 145°F (63°C) for three minutes and 150°F (66°C) for one minute. PSE patties cooked to 145°F (63°C) appeared similar to normal patties cooked to a medium degree of doneness (160°F or 71°C).

Just as ground hamburger has been shown to demonstrate premature browning (Hague et al, 1994; Warren et al., 1996), PSE pork becomes tan at lower than expected endpoint temperatures. This is attributed to greater pigment denaturation in PSE meat.

A difference in cooked color was also evident in patties cooked while frozen versus those prepared from thawed meat. Patties cooked from the frozen state had a lower a* (redness) value at every endpoint temperature than the thawed patties. These patties looked like they were fully cooked, even at the lowest endpoint temperature of 145°F (63°C), and the lack of redness remained relatively constant for each endpoint temperature. Patties cooked from a frozen state also showed significant tan coloration. A difference as simple as whether the patty is thawed or frozen can cause a much different cooked appearance. Judging doneness by appearance alone can lead to under or overcooked patties, which leads to concerns of safety or quality.

The Lesson To Be Learned

Several interrelating factors can have a profound effect on the color of cooked pork. Muscle quality, muscle pH, cookery practices, pigment forms and endpoint temperature combine in a variety of ways, which create unpredictable cooked color in pork. Some products may brown before reaching the target endpoint temperature combination. Others may be pink when prepared to the proper temperature. Cooking all pork to a white or tan color will result in overcooked meat that often is less flavorful, juicy and enjoyable. The key is monitoring the temperature to ensure that the meat is heated to a safe endpoint temperature without overcooking.

So, how can you tell when your pork is safe to eat if color isn’t a reliable indicator of doneness? Use of a meat thermometer is essential to assuring the quality and safety of cooked pork. The thermometer must be properly calibrated to be effective. It may seem like a nuisance, but measuring the temperature in meat during cooking will result in confidence in product safety and a more enjoyable eating experience.

References

AMSA (American Meat Science Association. 1995. Beef Steak Color Guide. Amer Meat Sci Assoc, Savoy Il 61874 USA.

Cornforth, D. 1991. Methods for identification and prevention of pink color in cooked meat. Amer Meat Sci Assoc, Savoy Il. Proc. Reciprocal Meat Conf. 44:53-58.

Cornforth, D. 1994. Color – its basis and importance. In: Pearson, A.M. and T.R. Dutson, editors. Quality attributes and their measurement in meat, poultry and fish product. Publ: Blackie Academic and Professional. Adv. in Meat Res. 9:34-78.

Faustman, C., J.L. Johnson, R.C. Cassens, and Doyle, M. P. 1990. Color reversion in beef. Influence of psychrotrophic bacteria. Fleischwirtsch. 70:676-679.

Ghorpade, V. M., D.P. Cornforth and D.V. Sisson. 1992. Inhibition of red discoloration in cooked vacuum-packaged bratwurst. J. Food Sci. 57:1053-1056.

Hague, M.A., K.E. Warren, M.C. Hunt, D.H. Kropf, C.L. Kastner, S.L. Stroda and D.E. Johnson. 1994. Endpoint temperature, internal cooked color, and expressible juice color relationships in ground beef patties. J. Food Sci. 59:465-470.

Hawthorne, S.A., R. Lien, M.C. Hunt and D.H. Kropf. Pork Chop Cooked Color Guide. K-State Research and Extension and the Nat. Pork Producers Council and Natl. Pork Board, Des Moines, IA.

Hawthorne, S.A., R. Lien, M.C. Hunt and D.H. Kropf. Ground Pork Cooked Color Guide. K-State Research and Extension and the Nat. Pork Producers Council and Natl. Pork Board, Des Moines, IA.

Hunt, M.C., O. Sørheim and E. Slinde. 1999. Color and heat denaturation of myoglobin forms in ground beef. J. Food Sci. 64:847-851.

Lien, R., M.C. Hunt, S. Anderson, D.H. Kropf, T.M. Loughin, M.E. Dikeman and J. Velazco. 2001. Effects of endpoint temperature on the internal color of pork patties of different myoglobin form, initial cooking state and quality. J. Food Sci. In Press.

Lien, R., M.C. Hunt, S. Anderson, D.H. Kropf, T.M. Loughin, M.E. Dikeman and J. Velazco. 2001. Effects of endpoint temperature on the internal color of pork loin chops of different quality. J. Food Sci. In Press.

Mendenhall, V.T. 1989. Effect of pH and total pigment concentration on the internal color of cooked ground beef patties. J. Food Sci. 54:1-2.

Trout, G.R. 1989. Variation in myoglobin denaturation and color of cooked beef, pork, and turkey meat as influenced by pH, sodium chloride, sodium tripolyphosphate, and cooking temperature. J. Food Sci. 54:536-548.

Warren, K.E., M.C. Hunt and D.H. Kropf. 1996. Myoglobin oxidative state affects internal cooked color development of ground beef patties. J. Food Sci. 61:513-515,519.

Pork Quality Endpoint Temperature and Time at that Temperature

145°F (63°C), 3min 150°F (68°C), 1min 160°F (71°C), 1sec 170°F (77°C), 1sec

Normal Pink Slightly Pink Very Slightly Pink Tan/White

Normal-injected Pink Slightly Pink Very Slightly Pink Tan/White

PSE Slightly Pink Very Slightly Pink Tan/White Tan/White

DFD Definite Pink Definite Pink Pink Slightly Pink

Table 1 – Internal Color of Cooked Pork Loin Chops

Table 2 – Internal Color of Cooked Pork Patties