Authors: LaVerne E. Stetson, Agricultural Engineer, USDA-ARS, Lincoln, Nebraska; Eldridge R. Collins, Jr., Virginia Polytechnic Institute and State University; Gerald R. Bodman, University of Nebraska

Reviewers: Richard A. Peterson, Northeast Agriculture Technology Corp, Ithaca, NY; Greg Stark, Biological and Agricultural Engineering, Texas A&M University, College Station, TX

Introduction

Proper design and installation of swine facility electrical systems are crucial to using electricity efficiently, providing safety for workers and animals, and minimizing potential fire loss. A majority of all farm fire losses are related to electrical system failure (Figure 1). Many wiring practices that are acceptable for use in our homes are unsafe when used in livestock housing because of exposure to dust, moisture, corrosive gases, and physical damage. Inferior wiring causes hazardous conditions for livestock and humans, expense of early rewiring of many buildings, and possible fires. Even when fires do not occur, poor wiring may contribute to higher maintenance costs. The mere fact that a system “works” doesn’t speak for its safety. Special wiring methods and components are needed for swine structures.

Objectives

- Introduce basic electrical equipment and wiring techniques used in swine facilities

- Identify potential wiring problems in current and new swine buildings

- Educate the producer to advise the electrician on how the building should be wired to allow maximum production efficiency and safety

Wiring standards

The standard for electrical work in the United States is the National Electrical Code® (NEC) published by the National Fire Protection Association. The NEC is a guide to selection and safe installation of proper materials. The NEC has become law in many states, but often there is limited inspection or enforcement in rural areas. In other states, agricultural structures are exempted from national, state, or local codes, so NEC practices often are not followed. Nevertheless, the NEC provides a standard (Article 547) for wiring swine buildings or other damp corrosive environments. Good practices often go beyond the bare minimum of the NEC to minimize fire hazards and reduce future maintenance problems. Because of the potential impact a fire loss can have on the total swine enterprise, all wiring should meet or exceed the minimum standard. The lowest priced electrical system is seldom the most economical. This leaflet does not provide sufficient information to properly design and install an electrical wiring system, nor does it describe all specialty devices, mechanical protection, and special requirements for feed handling and grain storage facilities with severe dust problems. For these, consult with a qualified electrician having training, experience, and knowledge of the National Electrical Code® (NEC) and proper wiring practices. Assistance is often available from your power supplier in planning and installing the distribution system to your building. Some companies will not insure buildings wired by older commonly used methods. Check with your insurance company before beginning construction to determine insurance requirements.

Farm building requirements

Dry farm buildings generally do not require special wiring materials or procedures. Such structures include garages (detached from houses), machine sheds, shops, and similar buildings. These buildings may normally be wired with the same materials commonly used in residences and in accordance with standard procedures and practices of the NEC. Dust-ignition-proof wiring systems should be used in extremely dusty feed processing areas. However, most small feed-grain handling centers are not classified as areas requiring dust-ignition-proof wiring and should be wired like swine structures described below.

Open and enclosed swine housing structures and other buildings that are washed periodically should be considered damp and corrosive atmospheres. Ammonia, hydrogen sulfide, and other corrosive gases, in combination with moisture and dust, hasten deterioration of electrical components. Many existing swine buildings have been wired using practices and materials that cannot withstand these conditions. Many older buildings have electrical systems that have deteriorated to the point of danger. The following discussion will focus on practices that reduce electrical system deterioration and its associated fire hazard, and foster efficient and safe use of electricity.

Materials for wiring

Equipment and methods necessary to meet the special requirements of swine housing are different from residential wiring. Therefore, plan ahead! Many of the materials may be available only from wholesale electrical supply houses. Use specification grade switches and receptacles rather than household grade equipment. All materials and equipment should bear a seal indicating they are listed by Underwriters’ Laboratories (UL), or by some other recognized testing laboratory.

Cable and conduit. Either Type UF cable or non-metallic conduit (Figure 2) can be used for wiring circuits in swine buildings. All wiring should be attached to interior surfaces of the building and not concealed within wall cavities, ceilings, or attic spaces. Surface mounting eliminates the need to make holes in the continuous vapor barrier, thus reducing the risk of warm, moist room air moving into wall or ceiling cavities and attics with resulting condensation. Surface mounting also reduces the risk of rodent damage and allows periodic inspection and repair.

Damage more serious than simple wet insulation may occur when electrical wiring is involved. Electrical boxes recessed in walls or ceilings will be cold during winter, thus becoming “condensation boxes.” As a result, switches, wire junctions, duplex outlets, and circuit breakers will corrode rapidly which may result in a short-circuit. When cables or conduits are extended into cold wall cavities or ceiling and attic spaces, cold air and condensation follows the cable or conduit (by draining or wicking) into electrical fixtures and boxes. When this occurs, corrosion and increased circuit resistance—with associated overheating of wiring or equipment—are greatly increased. Cables and conductors with non-waterproof covering also can lead to current leakage through the insulation, which may cause problems with stray voltage and increased potential for electric shock.

Surface wiring with cable is relatively easy, saves materials and labor, and is generally is acceptable except where subject to physical damage. Type UF cable is recommended because it is moisture resistant and allows use of weatherproof connectors and fittings at box connections. Do not use Type NM or NM-B cable in swine buildings.

Install cable where it will be protected from physical damage. Normally it should be installed on flat surfaces of walls and ceilings. Use nylon or plastic coated staples, or stainless steel nails and nonmetallic straps at a maximum of 4.5 ft intervals and within 8 in. of each junction or fixture box. If the building has exposed joists, beams, or trusses, run cable along the joist, beam, or truss chord. If it must run perpendicular to joists or ribs of metal ceiling or wall liners, install cable on a 1-in. x 2-in. running board. Sharp bends should be avoided; minimum bend radius is five times the cable diameter.

Conduit offers an alternative to Type UF cable, especially where wiring is subject to physical damage or where conduit may facilitate use of multi-conductor control circuits. Conduit requires adequate sealing to prevent vapor condensation when conduit goes between high and low temperature areas. Rigid Schedule 40 PVC conduit is recommended. Provide extra protection in areas subject to physical abuse by animals or equipment. PVC conduit is available in 10 ft and 20 ft lengths, and in commonly used diameters of 1/2, 3/4, and 1 in. Larger conduit for large motors or service entrances is also available. Single strand wire rather than cable is used in conduit. Select wires with a Type W designation (RHW, THW, THWN, or XHHW). Use a bare or green insulated copper wire of the same size as line voltage wires for grounding. All equipment MUST be grounded.

Mount conduit on the surface of interior walls or the ceiling. Conduit (1/2- to 3/4-in. diameter) should be supported at 3 ft (maximum) intervals with nonmetallic fasteners. PVC conduit elbows and offsets are available, or straight conduit can be bent using a “hot box” or hot air blower, but never use an open flame. Maintain a circular cross-section of the conduit throughout the bend. No more than the equivalent of four quarter bends (360 degrees total) may be installed between junction boxes and/or fittings.

PVC conduit can be cut with a fine-tooth saw or a special cutter. Ream or file the ends smooth after cutting. Permanent joints can be made using PVC connectors and solvent weld cement, or temporary joints can be made using threaded adapters with rubber washers or 0-rings.

Allow for thermal expansion and contraction in each conduit circuit. Also, install at least one 6 in. expansion joint per 50 ft of conduit.

Install conduit to prevent entry of dust, water, and vapor. If the conduit must be exposed to widely differing temperatures, such as where it passes through the outside wall of a heated building, or between two different rooms, the inside of the conduit must be sealed where it passes from a warm to a cool area using electrician’s duct sealer. In this way, moisture laden air in the warm conduit will be prevented from entering the cold conduit and condensing.

Use flexible wiring methods for fans and other equipment. Liquid tight, flexible non-metallic conduit with stranded conductors is one option. The maximum length of liquid tight flexible conduit permitted is 6 ft so careful planning of the overall electrical system is required. Electrical nonmetallic tubing (ENT) is rated for wet locations but is not recommended because the deep corrugations make it impossible to sanitize and it is not rated for outdoor temperatures. Metal flexible conduit, either bare or liquid tight, is NOT permitted in livestock buildings. Flexible cords with water-proof and dustproof strain-relief fittings can be used. Select cords that are rated for wet usage such as STEW, SEW or SJTEW.

Boxes and fixtures. Corroded metallic boxes and fixtures often lead to electrical system failure. Despite the higher cost and lack of ready supply in some areas, molded plastic boxes and other components are required. Gasketed covers are necessary on all boxes to seal wire splices, switches, and other electrical contact surfaces from exposure to dust, moisture, and corrosive gases. Moisture-proof receptacle boxes with spring-loaded covers are required. Standard metal boxes with screwed-in-place face plates (Figure 3) are not permitted. Switches also should be moisture-proof, either by means of spring-loaded covers, moisturetight switch levers (Figure 4), or moisture-tight covers with flexible press switches. General use switches and controls, although cheaper, are prone to corrosion and early failure. Moisture- and explosion-proof controls last longer and are safer. Do not use brown Bakelite® fixtures in livestock buildings!

All connections should be moisture- and dust-tight. Where surface wiring is used, totally nonmetallic cableto- box connectors are available with tapered hub, threads and a neoprene, rubber, or plastic bushing sized and shaped to fit the cable. When connected to a box, the bushing is compressed to form a seal. Select boxes that are made to fit the tapered hub connectors. Moisture- and dust-tight connectors also should be used to connect conduit to boxes and fixtures.

All cable or conduit should enter electrical boxes from the side or bottom (Figure 5) if possible. Then, if condensation occurs in or on the cable or conduit, or water accumulates during wash down, it will not drain onto electrical contact surfaces or leak into the box and corrode or short-circuit electrical components.

Mount receptacles and light switches where they will be protected from animals and water. A rule of thumb is to place boxes at least twice animal height, or at least 4 ft above the floor unless extra protection is provided. Provide 6 to 8 in. of wire inside each box to allow easy connections, plus a little extra in case switches, outlets, or fixtures are later replaced. Avoid placing boxes, cable, conduit, or fixtures on the ceiling within 6 ft of ventilation air inlets which direct air across the ceiling; otherwise the devices may deflect cold, fresh air onto young pigs and chill them.

Lighting

Incandescent and fluorescent are the two types of lighting most common in swine buildings. Each type of fixture has different properties of light output, color, and maintenance which might make it more suitable for special tasks. However, for most swine structures the decision between the two types will be based on cost and service.

Incandescent fixtures have a low initial cost and operate well in most conditions including low temperatures. Their light efficiency is low, so it takes more fixtures to provide the desired lighting level and they are relatively expensive to operate. Bulb life is also short, usually about 750 to 800 hours for 100 to 150 watt (W) bulbs. Fixtures should be dust- and moisture-resistant with a heat-resistant globe to cover the light bulb (Figure 2). Glass globes may crack when hot and exposed to wash water while plastic globes will not. Fixture boxes can become quite hot when used with globed fixtures. Type UF cable conductors have a temperature rating of 90 C. Check the temperature rating of the incandescent fixture. Some fixtures are labeled for conductor temperatures of 60 or 90 C. If there is no label or if the label indicates higher than 90 C, the safe way to avoid wire insulation failure from heat buildup is to install a junction box near the fixture and extend conduit and type SFF-1 conductors into the fixture box. Some new incandescent fixtures are designed to allow wiring with 60°C rated conductors. Because of the temperatures in heat lamps Porcelain sockets are mandatory for heat lamps.

Fluorescent fixtures cost more than incandescent but pro- duce 3 to 4 times more light per watt of electricity. If fluorescents are turned on and off frequently (less than a 10- minute burn cycle), lamp life will be reduced; incandescents would be a better choice for such use. But if light will be on for more than 10 minutes, fluorescents provide higher efficiency. Lamp life ranges from 7,500 hours for short use cycles to 20,000 hours for long use cycles. Fluorescents are best used indoors, since standard units do not perform well below 50°F without special ballasts. Ballasts which will work at 0°F are available. They also are more sensitive to relative humidity higher than 65%. Because of the damp, corrosive conditions normal in swine housing, fixtures with fiberglass enclosure and polycarbonate (Lexan®) covers are most serviceable. Heat buildup is less of a problem in fluorescent lighting fixtures. While not acceptable for some incandescent lighting, Type UF cable can be extended directly into fluorescent fixtures if the conductors are kept away from the ballast.

Provide enough light so inspection and work can be done efficiently. Each room should have at least two lighting circuits; two rows of lights on separate switches will provide two levels of lighting intensity. If ceiling and wall surfaces are light, no reflectors are needed. However, if surfaces are dark, provide reflectors. A guideline for light placement in swine housing is to provide one row of lights over each row of pens or stalls, and one row along the feed alley. At least one light should be installed over every other pen partition. Table 1 recommends the amount of lighting for various building purposes. For example, a 24-ft wide nursery could be illuminated to 10 foot-candles with (0.28 x 24 x 1) = 6.72 watts (W) of fluorescent lighting/ft of room length, or (1.00 x 24 x 1) = 24 W of 150 W incandescent lighting/ft of room length. For a 25- ft long room, this would mean two single-tube fixtures (6.72 W/ft of room length times 25 ft of length) on each side of the room, or two 150-W incandescent fixtures (24 W/ft of room length times 25 ft of length) on each side. For wider buildings, you may want to consider additional rows of lighting. Observe wattage limitations on incandescent bulb fixtures. Many of them have 60- or 75-watt limitations.

Circuits

Have an electrician or other knowledgeable person calculate circuit sizes because of the special heavy uses of electricity in hog buildings (heat lamps, portable motors, and other equipment). Circuits should include both those for general purpose and those for special equipment. General purpose circuits include lights and duplex convenience outlets (DCO). Equipment circuits include those for ventilation fans, heaters, fixed equipment, appliances over 1,500 W, motors exceeding 1/3 hp, and special purpose outlets (SPO) for uses such as high pressure washers.

As a guide, a general purpose circuit should be computed allowing 1.5 A per light fixture or DCO if not used for motors or heat lamps. Use the actual load value for DCOs and SPOs that supply motors, heat lamps, floodlights, or other large power users. Use #12 AWG copper wire (Table 2) and a 20- A circuit breaker for each 20 A of calculated electrical load. Circuits should not be continuously loaded to more than 80% of their designed capacity. Where circuits serve heating lamps, ventilation equipment, or other continuous or extended use equipment, the 80% load factor is required by the NEC, so plan the number of circuits accordingly. If each DCO will be used with heat lamps or other large resistance loads, circuit load should be calculated as follows:

Amps (A) = Watts (W) Volts (V), where A = current flowing through the conductor W = total power to be in service on circuit V = 120 V or 240 V service

Remember, if the circuit will be continuously loaded, such as with heat lamps, a 20-A circuit should be planned to carry only 16 A (80% of its actual rated load).

Branch circuits with only one motor should be sized for 125% of the motor full load current rating. For example: for one 8-A motor on a circuit, 8 x 1.25 = 10 A. If more than one motor will be on a circuit, rate the largest motor at 125%, and add the others at 100% of full load current rating. Additional loads on this circuit should be added at 100% of their full load current.

General purpose circuits wired with #12 AWG copper wire should have no more than a 20-A connected load; #14 AWG copper wire circuits should have no more than a 15-A connected load. New general purpose circuits smaller than 20-A (#12 AWG, copper) capacity are not recommended except for specific loads.

Size all conductors based on length of run as well as connected load. Long runs of undersized wire result in wasted energy and reduced performance of lights and electrical equipment. Each branch and feeder circuit segment should not exceed 2% voltage drop, and should never be smaller than #12 AWG (copper). Maximum combined voltage drop for service drops, feeder and branch circuits should not exceed 5% to the most distant DCO. The relationships between current, circuit length, voltage drop, and wire size are given in Tables 3. Almost all equipment under 100A has terminals rated for 60 C. The conductor ampacities in Table 3 are selected for the 60 C ratings.

Stationary equipment should be permanently wired into moisture-proof boxes as described earlier. This will minimize problems of moisture and dust entering the wiring system. Suspended appliances, lighting fixtures, and heating equipment should be provided with mechanical support such as chains and not suspended by their electrical supply wires, conduit, or cords. Minimize the use of extension cords.

High pressure washers must be ground fault circuit interrupter (GFCI) protected. A GFCI mounted on the machine or built in as part of the service cord provides the most flexibility for use and best protection. Even with GFCI protection, an equipment grounding conductor must be part of the wiring system to the washer. (Note: An equipment grounding conductor is required on all equipment.) Attaching a grounding wire from a ground rod to the high pressure washer provides inadequate protection and is not allowed as the only grounding method.

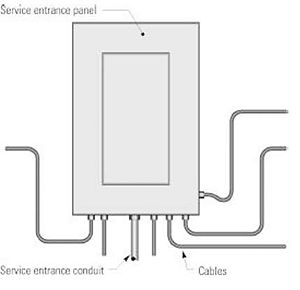

Electrical supply system

The electrical supply system is the “heart” of the building electrical system and consists of service conductors from the power supply, the main disconnect, one or more distribution panels (DP), and associated equipment. Often the main disconnect and DP will be in the same panel. Be sure that service conductors and equipment are large enough to provide electrical capacity for present and future needs. Minimum supply service for farm buildings is 60 A, but most modern buildings require at least 100 A or larger; your power supplier can help in determining the proper service supply. An undersized service supply is unsafe and inefficient and reduces the longevity of the system and equipment.

Where building openings such as doors, hatches, or windows are used for transfer of materials between the inside and outside of the building, overhead service conductors must be out of reach. Portable elevators and other equipment must be maneuverable into openings with minimal risk of contacting overhead wires. Therefore, have the point of attachment of overhead service conductors or other wiring no closer than 10 ft on either side of the opening, and at least 3 ft above. Under no circumstance should the point of attachment be below such openings. A minimum clearance of 18 ft should be provided above all driveways. Remember: clearance will decrease in warm weather as thermal expansion causes conductors to sag. Contact of conductors with equipment can kill!

Each circuit should be protected in the DP with its own fuse or circuit breaker selected to correspond to the size of the conductors used in the circuit. Do not load circuits to more than 80% of their current-carrying capacity (Table 2). This limitation is especially important for circuits loaded continually for long periods of time as with fans or heat lamps. Where fuses are used, they should be of the Type S. Fuses should be sized for the current carrying capacity of the conductor or less for specific loads such as a motor.

Location of DP can affect its rate of deterioration. Never install a DP recessed into an outside wall. Lack of adequate insulation behind the panel can result in condensation within the box and rapid corrosion of electrical equipment. Even surface mounted DPs, if possible, should not be mounted on the inner surface of an outside wall for the same reason.

Avoid problems by locating the DP outside the dusty, humid, and corrosive environment of the animal housing unit. The environment is less likely to be harsh in an entry hall, office, or utility room, and the DP could be located there using a NEMA 3R enclosure with corrosion-resistant finish. If the DP must be located in a room with animals, use a moisture-tight nonmetallic unit (NEMA 4 or 4X enclosure). For safety and convenience, be sure to provide at least 3 ft of open, accessible work space in front of the DP. The door or cover must be capable of being opened a full 90 degrees.

Where possible, place DPs near the largest electrical loads. This will minimize requirements for long runs of larger, more expensive conductors and eliminate energy-wasting voltage drops.

Surface mount DPs on a fire resistant surface such as concrete or 26 gauge (minimum thickness) galvanized steel over a fire-resistant material. Surface mounting DP’s have raised dimples to provide the proper ventilation behind the DP. If overheating does occur with this installation, the air space will help protect the combustible wall of the building. The spacing arrangement also will help maintain the DP at room temperature, reducing the possibility of condensation, and will eliminate entrapment of moisture, dust, manure, and other corrosive matter.

As noted earlier, service conductors and branch circuit conduit or cable should enter at or near the bottom of the main disconnect or DP. In this way, draining of water and condensate down the cable or conduit and into the panel can be more easily avoided.

Where existing DPs have been installed so that condensation may develop during cold weather, a small amount of heat installed around, on, or in the DP may help alleviate the problem. If possible, first install some insulation behind the panel. If the DP is surface mounted, it may be possible to wrap the perimeter with a heat tape. Another alternative during cold weather is to mount a heat lamp in a holder outside the panel directed to warm the DP. Take care that the bulb is not close enough to wires, walls, or other materials that it might cause damage or fire.

Since some corrosion may develop on contact surfaces of DP circuit breakers, a monthly schedule to switch circuit breakers off and on should be established. This will help wear away minor amounts of corrosion which may develop at the breaker contact surface, and which could contribute to electrical resistance and overheating. Circuit breakers that are not switched off periodically are frequently found “frozen” into the “on” position. In such cases, it is unlikely they would trip under high current load, so the intended safety feature no longer exists.

Grounding

Safety requires two systems of grounding:

1. System grounding—the connection of the grounded service conductor through an acceptably sized (based on service capacity) conductor to an acceptably sized grounding electrode.

This grounding electrode conductor must be connected at the terminal or bus bar to which the grounded service conductor (commonly called the “neutral”) is terminated in the main disconnect. Grounded conductors carry current during the normal operation of 115-V equipment and must have white or gray insulation or marking.

2. Equipment grounding—the grounding or bonding of noncurrent carrying equipment such as motor frames back to the service entrance panel grounding bar.

Failure to provide proper equipment grounding may contribute to stray voltage problems causing stress and danger to animals and humans. The NEC requires that grounding conductors be bare or have a green or green with yellow stripe insulation. This conductor is designed to carry adequate current under fault conditions to open a circuit breaker or fuse and is commonly referred to as the “ground” wire.

Grounding electrodes are required at all service entrances using approved bonding (clamps) which are properly sized based on service capacity. Rods of 8 ft (minimum) commonly are used, but the NEC does allow other methods. Resistance from the grounding electrode to surrounding soil must be 25 ohms or less. If more than one electrode must be used to get this resistance, rods should be spaced at least twice the length of the ground rods apart and interconnected with a noncorrosive conductor and ground rod clamps approved for that purpose. Electrode resistances of 2 to 5 ohms are desirable for improved safety and lightning protection. Use clamps designed and rated for direct burial. The grounding conductor from the service equipment to the grounding electrode should be protected from physical damage and should be continuous.

To minimize danger from electrical faults, the NEC requires all metallic equipment including building components within 8 ft of the floor or soil surface to be bonded to the system grounding electrode through the branch circuit grounding or other appropriate grounding conductors. Although separate grounding rods may be used in these cases, they must be in addition to and bonded to the main system electrode. All metallic water lines, gates, flooring materials, animal crates or pens and similar equipment must be bonded together and to the electrical system grounding electrode.

All new wiring should include equipment grounding conductors. Equipment such as motors or electrically-heated waterers should be grounded by means of an equipment grounding conductor connected to the grounding bus at the DP. Installing a ground rod on such equipment as a substitute for an equipment grounding conductor is not permitted, but a ground rod may be installed as a complement to the grounding conductor.

Fans

No more than two fans should be wired per circuit in an environmentally-controlled swine room. With fractional horsepower motors, or when more than one fan is included on a branch circuit, secondary fusing is necessary to provide adequate overcurrent protection of individual fan motors with a locked rotor. The use of automatic reset fans is not recommended because fans often continue to restart until they finally burn out the motor. Also, there is a risk involved in that a person who sees a fan not operating could begin to check to determine why it is not running and the automatic restart could re-engage, causing personal injury. The manual reset is a much preferable and safer protective measure for motors that operate fans, feed and material handling systems.

A fused switch or properly sized circuit breaker installed in a corrosion resistant box, and located within 5 ft to 10 ft of each fan is required for safety during cleaning and maintenance. Fused switches are available to meet both individual fan fusing and switching requirements. Use a time-delay fuse sized at 150% (125% for motors without thermal protection) of the motor full load current rating. At least two fan branch circuits from opposite sides of the 230 V entrance panel should be provided in each environmentally-controlled room. Then, if one circuit fails, the room can still be ventilated.

Because of dust and corrosion, use only totally-enclosed motors for swine buildings. Open motors are more prone to early failure, are more apt to cause fire and explosions, and are not allowed in livestock buildings. Fans and other motors, for example, feed delivery augers, heaters, curtain controllers, etc., should be permanently wired. Do not use cord and plug connections. Permanent wiring maintains the integrity of the watertight wiring system. Plugs require receptacle covers to be open continuously, allowing moisture and corrosive gases to enter the wiring system.

Inspections

Few states require the inspection of agricultural electrical systems. However, some power suppliers require an inspection before electrical service will be provided. Some insurance companies require inspections, while others offer reduced premium rates for buildings that are inspected and verified as meeting NEC requirements. Consult your power supplier and insurance company, and use available inspection services before putting newly wired facilities into use.

Summary

Quality electrical wiring practices often are overlooked when remodeling or constructing new swine buildings. The moist and corrosive conditions in these buildings necessitate suitable practices and materials to increase the life of the electrical system and to reduce the likelihood of loss of property, animals, and income, or personal injury caused by electrical failure.

Additional References

Agricultural Wiring Handbook (Thirteenth Ed.). National Food and Energy Council, Columbia, MO 65203.

Electrical Wiring Systems for Livestock and Poultry Structures. National Food and Energy Council, Columbia, MO 65203.

Farm Buildings Wiring Handbook, MWPS-28. Midwest Plan Service, Iowa State University, Ames, IA 50011.

National Electrical Code®. Published by and a registered trademark of the National Fire Protection Association (NFPA), Quincy, MA 02269.

Reference to products in this publication is not intended to be an endorsement to the exclusion of others which may be similar. Persons using such products assume responsibility for their use in accordance with current directions of the manufacturer.

The information represented herein is believed to be accurate but is not guaranteed. The authors, reviewers and publisher assume no liability in connection with any use for the products discussed and it makes no warranty, expressed or implied, in that respect, nor can it be assumed that all safety measures are indicated herein or that additional measures may be required. The user, therefore, must assume full responsibility, both as to persons and as to property, for the use of these materials including any use which might be covered by patent.

All pictures © MWPS (MidWest Plan Service), Iowa State University, Ames, IA., www.mwpshq.org. Used with permission: Wiring Handbook for Rural Facilities (MWPS-28), 2006.

Figure 1. A majority of all farm fire losses are related to electrical system failure.

Figure 2. Either non-metallic conduit or Type UF cable wiring circuits may be used in swine buildings. Wiring should be attached to interior surfaces of building—not concealed in wall, ceiling, or attic—to reduce chance of condensation and rodent damage and facilitate periodic inspection.

Figure 3. Standard metal boxes are not suitable for swine housing because of susceptibility to corrosion and subsequent electrical system failure. Boxes are required to be moisture-proof and have spring-loaded covers.

Figure 4. Switches should be moisture- proof, either by means of moisturetight levers, springloaded covers, or moisture-tight covers with flexible press switches.

Figure 5. All cable or conduit should enter electrical boxes and distribution panels from the side or bottom if possible.