Contents

- 1.1 Overview

- 1.2 Introduction

- 1.3 Non-Meat Ingredients

- 1.4 Sodium phosphates

- 1.5 Salt or sodium chloride

- 1.6 Sodium lactate

- 1.7 Potassium lactate

- 1.8 Sodium diacetate

- 1.9 Lemon juice and organic acids

- 1.10 Flavor agents

- 1.11 Total level of added ingredients and injection level

- 1.12 References

Originally published as a National Pork Board/ American Meat Science Association Fact Sheet.

Author:

Rhonda Miller, Texas A&M University

Reviewer:

Scott Eilert, Excel Corporation

Overview

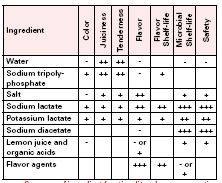

Enhanced pork is the process of adding non-meat ingredients to fresh pork to improve the eating quality of the final product where eating quality is defined as the juiciness, tenderness and flavor of pork. In adding these ingredients, the color and the shelf-life of the final product may be impacted either negatively or positively. Shelf-life of pork can be affected either by the microbial levels in the final product or by color or flavor deterioration and the addition of non-meat ingredients may influence different aspects of shelf-life. The major ingredients used in enhanced pork are water, sodium phosphates, salt, sodium lactate, potassium lactate, sodium diacetate and varying flavoring agents of which lemon juice has been singled out for use in some products. What do these non-meat ingredients do for or in the final product? A summary of each ingredient’s functionality is presented below. However, when some ingredients are used together, the combined effects may provide greater positive or negative effects for different quality attributes. These effects are discussed in the paper, but are not identified below.

Introduction

The term “Enhanced Pork” evolved from the addition of an injection solution into pork to enhance the eating characteristics of the final product. The use of injection or the addition of ingredients to meat is a historically old practice. Non-meat ingredients are used to improve juiciness and/or tenderness, enhance flavor, improve color, stabilize color, increase shelf-life, improve safety, or increase water-holding capacity in the final product. Additionally, some ingredients work synergistically with other ingredients to further enhance their functionality. Enhancement of fresh pork provides opportunities to improve the overall quality of fresh pork and to reduce the amount of variation in pork quality. Enhancement is not a method to improve low quality pork, but it is a method being used by the pork industry to improve the overall quality of fresh pork in the retail meat case. The purpose of this paper is to identify and explain the functionality of non-meat ingredients currently used in enhanced, retail pork products.

Non-Meat Ingredients

The United States Department of Agriculture (USDA), Food Safety and Inspection Service (FSIS) regulates the addition of injection solutions in meat. Based on the level or percentage of addition to the product, there is defined wording that has to appear on the meat label in order for the product to pass FSIS inspection. The first requirement is that the total level of injection that is added to the product has to be defined. In enhanced products the total amount of added ingredients typically range from 7-15% addition to the beginning or green weight of the meat. For meat containing greater than 10% total added ingredients, the label must carry the words containing up to (the actual added level)% of a solution followed by the list of ingredients in descending order of addition in the final product. When using injection levels at less than and up to and including 10%, while the ingredients have to be listed in the descending order of predominance, the label can read deep basted or marinated instead of containing up to. The term deep basted or marinated is considered a more positive consumer term on the label. Water traditionally has been used as a carrier for non-meat ingredients as most non-meat ingredients are water-soluble or can be suspended in water with agitation for subsequent addition to meat. As a result, water almost always is listed first on a label in the ingredient statement that identifies what has been added to the meat. The other non-meat ingredients are added for their functionality. The remainder of the discussion will concentrate on the most commonly used ingredients and their functionality.

Sodium phosphates

Sodium phosphates (SP) were originally used in meat injection solutions to enhance water-holding capacity. Their usage is regulated by USDA, FSIS and fresh meat products can not contain more than 0.5% in the final product. There are various forms of SP that can be added to meat products; however, sodium tripolyphosphate is the predominant phosphate in phosphate blends that are used in meat systems. The major sodium phosphates purchased commercially contain blends of different phosphates and these blends are used to increase the functionality of phosphates in meat systems. Sodium tripolyphosphate has an alkaline pH and even though meat is a very good buffer, the addition of sodium tripolyphosphate to meat systems increases the meat pH (Table 1). Increasing the meat pH improves water-holding capacity by moving the meat pH further from the meat protein isoelectric point. As the pH moves further from the isoelectric point (about 5.2 to 5.3 in red meat), water-holding capacity increases due to an increase in the amount of negative charges on the meat proteins that can bind water. The net result is an increase in the amount of water that can be bound to the meat proteins.

To understand if phosphates act in meat to bind water through an increase in pH, a study was conducted where they added three phosphate solutions that would create a low pH (5.0), a medium pH (5.5) and a high pH (6.0) in pork loin or inside ham roasts (Cannon et al, 1993). As pH decreased, the free water (%) decreased markedly, cook yield decreased, purge loss decreased, juiciness decreased and tenderness decreased. Therefore, the addition of sodium tripolyphosphate improves meat water-holding capacity and the subsequent meat quality aspects and the majority of this effect is due to its ability to increase meat pH.

The addition of sodium phosphates to meat systems has been shown to improve meat yields due to increased water-holding capacity (Table 1). As the level of SP increased, purge percentage in the vacuum-package or in the retail meat package decreased. Cook yield is another measurement of meat yields and as the level of SP increased, cook yield has been shown to decrease regardless of meat system and cut (Table 1).

As the pH of meat increases with the addition of SP, subsequent changes in meat color would be expected. As meat pH increases, meat becomes darker in color. The relationship between meat pH and color has been well established. As pH increases and the pH moves further from the isoelectric point, meat proteins bind more water on their negatively charged side chains. By binding more water, there is less water to reflect light and the meat appears darker in color. Additionally, pH affects the ability of myoglobin to oxidize to metmyoglobin (the brown color associated with meat spoilage). It has been shown that as pH decreases, myoglobin is more easily oxidized to metmyoglobin and the color of the lean was lighter or lower in color intensity. Also, at a higher pH, myoglobin, the main protein in meat that has pigment, does not degrade as rapidly with heat. During cooking, myoglobin degrades and as a result, meat goes from a red-based color to gray. If myoglobin does not degrade as rapidly with cooking, at the same internal cook temperature, pork with a higher meat pH will appear more reddish or not as well done. Many researchers have found that color became darker in both pork and beef when phosphates were added.

With increased water-holding capacity, meat with SP added has been shown to be juicier, have improved tenderness and there are some changes in meat flavor. When SP level increased from 0 to 0.2 to 0.4% in the final product, pork roasts were juicier and had incrementally higher percentage of moisture (67.57, 66.94 and 67.63%, respectively), but the addition of 0.4% SP resulted in lower flavor intensity scores and higher levels of salt intensity when compared to pork roasts that did not contain SP. As the higher level of SP resulted in higher cook yields, the lower flavor intensity is most likely a dilution effect due to higher amount of water in the final cooked product. The addition of SP alone is commonly associated with increasing the off-flavors such as soapy and sour. Two studies, one in pork (Sutton et al., 1997) and one in beef (Vote et al., 2000), reported increased flavor attributes with SP addition. In beef, they showed that using sodium chloride and sodium lactate in combination with SP, the soapy and soured flavors were not detected by the trained sensory panelists. It is hypothesized that the addition of these ingredients masks the soapy off-flavor of SP.

Sodium phosphate addition has been associated with changes in meat texture, especially when used at higher levels. Meat containing higher levels of SP have been characterized as more tender. The meat also has been shown to be softer, more rubbery, and it has been characterized as having a more processed meat-like bite. When the effect of sodium chloride and phosphates addition on the chemical and sensory properties of ground pork patties were studied, ground pork patties containing 2% sodium chloride and 0.5% phosphate were softer, less crumbly, juicier and more elastic than other treatments and the control (Keeton, 1983). In other studies, pork loins containing a 10% water and up to 0.5% SP in the final product tended to have either lower Warner-Bratzler shear force values, improved water-holding capacity and more tender, juicier pork chops, although cooking method influenced this relationship (Jones et al., 1989; Sheard et al., 1999)

The addition of SP to meat has been shown to have antioxidant properties that decrease the rate of lipid oxidation in meat. Oxidation of lipids has been associated with off-flavor development and non-microbiological spoilage. It has been shown that the addition of phosphates to ground pork patties reduced TBA values, a common measurement of lipid oxidation.

In regards to the effect of SP addition to meat and subsequent meat shelf-life, meat with a higher pH has been shown to be more conducive to microbial growth, especially those microorganisms involved in meat spoilage, either aerobic or anaerobic conditions. This is the same phenomena involved when comparing the shelf-life of dark, firm and dry meat (high pH), normal (average pH) and pale, soft and exudative meat (low pH) where high pH meat has a shorter shelf-life. While the addition of SP that pH decreased total plate counts in pork loin chops even those with high pH, SP addition is generally recognized as having inconsequential effects on microbial growth. The use of SP is driven by its ability to increase protein water-holding capacity. The ability of SP to limit growth of meat pathogens has not been extensively examined. This is mainly due to the lack of an antimicrobial effect of SP as previously discussed.

Therefore, it is generally recognized that the addition of sodium phosphates to pork increases meat pH; increases meat water-holding capacity that assists in reducing purge loss and cook loss; improves meat color, juiciness and tenderness; when used at higher levels, it may make meat too soft and the meat loses its textural identity; pork flavor may be diluted at high levels; and it may or may not improve shelf-life.

Salt or sodium chloride

The use of salt in meat to increase shelf-life and enhance flavor is an old practice. It also is used to improve water-holding capacity and results in subsequent improvements in purge loss and cook yields. It is usually the second ingredient on the label statement behind water and it is a conventional non-meat additive. Sodium chloride acts to improve water-holding capacity by lowering the isoelectric point of meat proteins and works without changing the meat pH. The swelling of meat proteins has been attributed to their ability to bind more water. Meat proteins have the ability to swell to twice their size in salt concentrations that are used in meat processing.

Sodium chloride addition contributes to the swelling of the proteins and similarly, the chloride ion has been shown to bind to the meat protein filaments and increase the electrostatic repulsive force between them. By increasing the repulsive forces, the protein structure matrix then unfolds and swelling occurs. The swelling provides a higher number of protein side chains that can bind water and therefore, water-holding capacity in increased.

Sodium chloride addition to meat has been associated with its antimicrobial properties. Historically, salt was added to meat to preserve it when refrigeration was not available. For this application, salt levels were very high and traditionally, salt was added either by rubbing the salt on the exterior surface or placing the meat in a high concentrated salt brine for a extended period of time. Salt levels used in enhanced and marinated products may have limited antimicrobial effects; it is the ability of salt to increase waterholding capacity that drives its use in enhanced pork products.

Sodium chloride addition also enhances meat flavor, has been associated with increasing basic salt taste and it has been shown to increase lipid oxidation. Sodium chloride is often added in combination with SP. The challenge is to balance the amount of sodium chloride addition with the amount of SP that is added to maximize water-holding capacity without getting too high of a salt flavor or altering texture. At too high of levels, pork will be too soft or it will have a more processed meat-like bite.

Sodium lactate

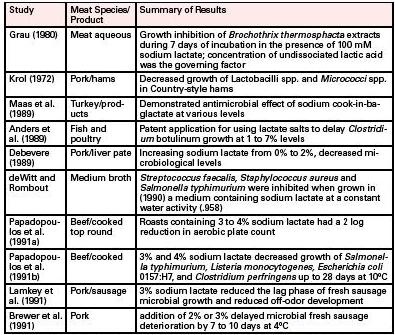

Sodium lactate, the salt form of lactic acid, has been used as a non-meat ingredient in the meat industry since the late 1980’s (Table 2). The initial work that resulted in a patent was conducted by Maas et al. (1989) who examined the use of sodium lactate to restrict development of botulinum toxin in cook-in-bag turkey products. Sodium lactate was approved for use at up to 2% as a flavor enhancer by USDA, FSIS (Federal Register, 1990), but it could be used at up to 4.0% on an individual basis if the company requested special consideration for it use based on its antimicrobial effects. The USDA, FSIS did not make a final ruling for use of sodium lactate as an antimicrobial agent as a petition to request its’ approval was not filed. The USDA, FSIS routinely approves labels with its usage above the 2% level and the industry began using sodium lactate in multiple pre-cooked meat products.

The addition of sodium lactate has been shown to improve overall color, help to stabilize color during storage and to increase the length of time that color is maintained during storage. The addition of sodium lactate has been shown to increase the meat pH that results in a darker colored lean (Table 2). The darker color lean in meat containing sodium lactate also has been shown to stabilize with storage. This stabilization of meat color with storage is most likely due to the higher pH that provides some protection against oxidation during meat storage. Myoglobin is the pigment in meat that gives meat its red color. When myoglobin is oxidized, it turns brown or is in the metmyoglobin state. Contributing factors for oxidation of myoglobin are pH, the amount of exposed light, microbial growth and time. At a higher pH, oxidation of myoglobin is not as rapid. Microbial growth also affects meat color. As microorganisms grow, they can either contribute to the oxidation of myoglobin or they can produce products that can cause off-color development. For example, when meat has reached the end of its shelf-life, the color of the lean sequentially turns brown. Microorganisms can contribute some of the brown color development by assisting in oxidizing the myoglobin to metmyoglobin. The other mode of action of microbial growth is when meat develops off-colors, like the green color associated with meat spoilage. The green color in spoiled meat is from sulphur binding to the ligand of myoglobin where the sulphur is derived from sulphur-producing microorganisms that are involved in meat spoilage. Therefore, sodium lactate appears to protect myoglobin so that it does not oxidize as rapidly by increasing the meat pH and by reducing microbial growth limiting the contribution that microorganisms make to myoglobin oxidation.

The addition of sodium lactate has been shown to increase meat juiciness. As sodium lactate increases cook yield when used in combination with low salt brines and it has humectant properties, improvements in juiciness in meat containing sodium lactate are not surprising. Whole muscle meat containing sodium lactate has been shown to be more tender. As sodium lactate addition has been associated with increasing meat pH that results in increased water-holding capacity and less cook losses, the resultant meat would expectantly be more tender.

Sodium lactate has been shown to enhance the cooked pork flavor and to limit the subsequent decline in this aromatic during refrigerated storage in pork products. As pork flavors declined during refrigerated storage, increased intensity of aromatics associated with lipid oxidation, the chemical reaction in lipids that can limit shelf-life of meat, have been reported. Therefore, sodium lactate addition has been shown to improve the pork flavor in these meats and to reduce the development of off-flavors associated with lipid oxidation. However, sodium lactate addition also has been associated with higher salt tastes, increased throat-burning mouth-feel, and higher levels of chemical aromatic flavor. These negative flavor attributes have been characterized as components of the sodium lactate itself. The addition of sodium lactate with other ingredients appears to decrease these effects and these effects are only slightly detectable at levels up to 3%.

As TBA values are a measure of lipid oxidation, many studies have reported TBA values as an indication of shelf-life and off-flavor development. While results are mixed, at abuse temperatures, lower TBA values have been reported in cooked beef roasts containing 2 to 4% sodium lactate. However, in pork sausage containing from 0 to 3% sodium lactate and stored at 4°C from 0 to 21 days, TBA values did not change. It appears that sodium lactate addition may provide some antioxidant effects, but these effects are most likely tied to its ability to limit microbial growth and therefore, sodium lactate indirectly assists in limiting lipid oxidation by decreasing the contribution of microorganisms to lipid oxidation.

The addition of sodium lactate at levels greater than 2% in the final product have been shown to increase the lag phase of spoilage microorganisms using aerobic plate counts in pork sausage, cooked beef top rounds, cooked comminuted turkey, cooked turkey breast, ground beef, ground pork and beef strip loins (Tables 2 and 3). This is a well documented and sodium lactate is most often added to meat products to assist in limiting microbial growth. It is generally recognized that sodium lactate increases the lag phase of microbial proliferation and delays the onset of logarithmic growth. The mode of action for sodium lactate has been hypothesized to be two-fold. First, the lactic acid portion of sodium lactate has antimicrobial properties as it can be incorporated into the microbial cell. Lactic acid then interferes or slows down the normal metabolic process that generates energy in the cell. This metabolic process is called glycolysis. Additionally, the addition of sodium lactate lowers the water activity of the meat and by lowering water activity, microbial growth is slowed. The sodium ion also has some antimicrobial effects as previously discussed.

Sodium lactate addition has been shown to limit the growth of food borne pathogens. Early work with sodium lactate showed a reduction in the development of botulinum toxin in cook-in-bag, comminuted turkey. It was concluded that sodium lactate delayed the production of botulinal toxin and that the effect was concentration dependent. Other work looked at the addition of 2, 3 or 4% sodium lactate on the growth of five major beef pathogens in cooked beef strips. It was shown that 3 and 4% addition of sodium lactate to cooked beef top rounds limited the proliferation of Salmonella typhimurium, Listeria monocytogenes and Escherichia coli 0157:H7 when compared to control roasts and those containing 2% sodium lactate. Therefore, sodium lactate provides some protection against growth of food borne pathogens, but it does not reduce their initial numbers.

Potassium lactate

Most of the early work examined the use of sodium lactate as a non-meat ingredient, but interest in adding a non-meat ingredient that did not increase the level of salt in the final product and that would not have any off-flavors associated with its use increased by the early 1990’s. Potassium lactate has a potassium ion substituted for the sodium ion in sodium lactate and it is used extensively in meat products.

Potassium lactate has been shown to increase meat color, improve juiciness and tenderness, enhance positive flavor attributes and decrease negative flavor attributes during storage, decrease microbial growth, and limit the growth of some major meat pathogens as previously discussed with sodium lactate. Potassium lactate can replace sodium lactate as a non-meat ingredient and have functionality similar to sodium lactate, but it does not have the off-flavor problems associated with sodium lactate.

In general, potassium lactate is used as a substitute for sodium lactate. However, research on its ability to limit growth of major meat pathogens has not been conducted, and while it has been shown to limit microbial growth and it most likely reduces the growth of major meat pathogens.

Sodium diacetate

Sodium diacetate recently has been approved for use in meat products as an antimicrobial agent. The Food and Drug Administration classifies it as GRAS (generally recognized as safe). It can be added alone, but many times it is added in combination with other antimicrobial agents such as sodium lactate or potassium lactate. Sodium diacetate is a compound containing 60% sodium acetate and 40% acetic acid. It is traditionally added at low levels in the final product, usually not greater than .2% in meat products and more commonly it is added at levels of .1 to .15% in the final product.

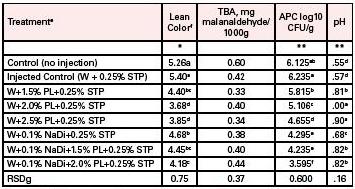

The addition of sodium diacetate alone or in combination with other ingredients, such as sodium lactate or potassium lactate, has been shown to not effect or to have a very limited effect on meat color (Anwar et al, 2000; Grones et al., 2000). As sodium diacetate is added at such low levels, it would not be expected to influence meat color even though its addition has been shown to decrease meat pH slightly (Table 4).

The addition of sodium diacetate was shown to not effect the juiciness of ground beef patties (Grones et al., 2001) or enhanced beef strip loin steaks (Anwar et al., 2001). As sodium diacetate lowers the meat pH (Table 4), it could possibly decrease juiciness as meat pH decreases slightly and as the pH is moving closer to the meat isoelectric point, a decrease in the water-holding capacity may be expected. Grones et al. (2001) reported a 5% decrease in cook yield of ground beef patties containing 0.15% sodium diacetate and 3% sodium lactate when compared to patties with 3% sodium lactate alone. However, sensory panelists did not report a difference in juiciness. It appears that as sodium diacetate is added at such low levels, the effect of lower pH on meat juiciness is not detectable. Similarly, sodium diacetate addition does not appear to significantly effect meat texture in ground beef or enhanced beef strip loin steaks. Again, as it is added at such low levels, it appears to not affect meat texture.

Sodium diacetate is sour in flavor due to having two acetate ions for each sodium. Grones et al. (2001) found slightly higher soured flavors in ground beef patties containing either 3% sodium lactate and .15% sodium diacetate or 2% sodium diacetate and .15% sodium diacetate, but the increase in sour was only slightly detectable by an expert sensory panel. Sodium diacetate addition did not affect the intensity of other flavor attributes by either enhancing or suppressing flavors in ground beef patties containing 0.15%. Weber (1997) found similar results in roast beef and turkey breast roasts. It appears that sodium diacetate is added at low enough levels that the flavor of meat products are not influenced by its addition.

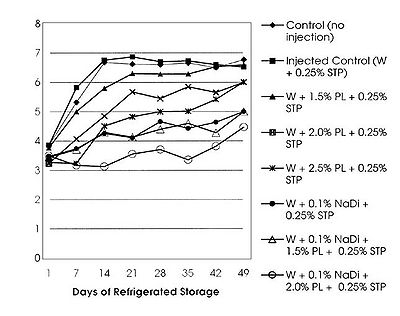

The main impetus for addition of sodium diacetate into meat products has been to decrease microbial growth. When sodium diacetate was added to the surface of refrigerated poultry, the skin surface pH was lowered and microbial growth decreased. Similar results were found when sodium diacetate was added to enhanced beef strip loin steaks (Figure 1). With increased storage, aerobic plate counts (APC) in beef strip loins steaks containing sodium diacetate were lower than either the APCs in control steaks or steaks containing potassium lactate. However, the lowest APCs were reported when sodium diacetate was combined with potassium lactate. Similarly, other reseachers have found lower APCs during storage in cooked beef and cooked turkey breasts that contained combinations of sodium diacetate at 0.15% and sodium lactate (2.5 or 3%).

Sodium diacetate also has been shown to limit the growth of some major meat pathogens. The addition of 0.28% sodium diacetate to ground beef has been shown to suppress APCs. When sodium diacetate was added at higher levels, the growth of some strains of Listeria; Escherichia coli; Salmonella enteriditis, hyersinia, and enterocolitica; gram-negative spoilage bacteria; and Lactobacillus fermentis were inhibited. When sodium diacetate was added to turkey meat slurries at level of 0.3 and 0.5% Listeria monocytogenes growth was delayed. The antilisterial activity of sodium diacetate to not only due to its pH lowering effect, but to the activity of the acetate ion on listerial growth.

Sodium diacetate is added as a non-meat ingredient mainly to retard microbial growth and to reduce the growth of some major food borne pathogens, mainly Listeria monocytogenes. The addition of sodium diacetate, mainly because it is used at low levels usually below 0.2%, does not affect meat color, juiciness, tenderness or flavor attributes.

Lemon juice and organic acids

The use of food grade organic acids, such as citric, malic, acetic, lactic, benzoic, sorbic and propionic acids, have been used to limit microbiological growth in food products. The antimicrobial effects of organic acids are mainly dependent on: 1) the sole effect of pH; 2) the extent of dissociation of the acid, which is related to the pH; and 3) the specific effect of the acid molecule (Acuff, 1991). At a given pH the antimicrobial activity of an acid is related to the ability of the acid to penetrate the cell, the part of the cell which is attacked and the chemical nature of the attack. Some manufacturers of enhanced pork are adding lemon juice or lemon juice solids as non-meat ingredients. Lemon juice is high in citric acid, is viewed as a “positive” additive by consumers, and may also be used to provide flavor.

The addition of organic acids, which usually will alter pH, can have detrimental effects on color stability if concentrations are too high within the system. For example, when a 10% water solution was added to mature beef, hotboned, cow top round so that the top rounds contained either .3M lactic acid, .3M lactic acid and .3 M calcium chloride, .3M calcium chloride, or water only, the top rounds containing .3M lactic acid or .3M lactic acid and .3M calcium chloride had lower aerobic plate counts (P<.05) than other treatments after 17 days of refrigerated storage. However, discoloration of the lean occurred in the top rounds containing the lactic acid treatments. While lactic acid aided in reducing aerobic plate counts in a hotinjected meat system, the level of lactic acid was detrimental to the color characteristics of the lean.

When lemon juice solids are added to the injection formula instead of lemon juice or natural lemon juice, it is to reduce the effect that the low pH of lemon juice has on discoloration of pork. Other strategies to overcome the negative effect of low pH that may be induced by lemon juice addition to meat is to micro-encapsulate the citric acid. Micro-encapsulation provides the opportunity to control or delay the effects of the acid whereas the acid would be activated upon degradation, disruption or melting of the encapsulation material.

The citric acid portion of lemon juice also has been shown to be an antioxidant. It is commonly used in food items to control lipid oxidation. Lipid oxidation is a chemical reaction that results in the development of off-flavors often described as rancid, old, cardboardy, painty and fishy. Additionally, meat flavors associated with the lean portion of the pork, such as pork lean flavor, decrease as lipid oxidation progresses. The decrease in the positive flavor attributes and the development of off-flavors associated with lipid oxidation is one method of limiting shelf-life of pork products, especially as pork has a higher amount of fatty acids with double bonds. Double bonds in lipids are what are oxidized during lipid oxidation and so pork is highly susceptible to this reaction. Therefore, the addition of citric acid has been shown to stabilize pork flavor during storage and to reduce the development of off-flavors associated with lipid oxidation.

Flavor agents

Flavor agents are added to pork to provide alternate flavor choices for consumers. Flavor agents also can be used to mask undesirable flavors from other ingredients such as potassium lactate or sodium lactate. Flavor agents can range from the addition of fresh ingredients, dehydrated ingredients, ground spices, spice extractives or oleoresins.

The addition of whole spices, while aesthetically desirable to the consumer, can decrease shelf-life either through addition of microorganisms contained within the spice or ingredient or by the inherent oxidation potential contained within the ingredient. Many spices, such as black pepper, are treated either by irradiation or by chemical decontamination methods to reduce the microbial population in the spice so that their addition does not affect shelflife. The oxidation potential of fresh ingredients can only be addressed by processing the ingredients to disenable the oxidation potential. When fresh ingredients like onions or green peppers are dehydrated, the oxidation potential of the vegetable would be reduced.

On the positive side, some spices and ingredients have antioxidant properties such as rosemary, garlic, spices, onions, and green peppers that improve flavor stability during storage. Additionally, clove, cinnamon, mace, oregano, allspice and nutmeg also have shown antioxidant properties. As a result of these antioxidant properties, spice extracts, oils and oleoresins, are currently in use as antioxidants in the meat and poultry industry. The spice extracts, oils and oleoresins are components of the original spice that can be added to meat products instead of the whole spice. The advantage of using only a component of the whole product is that the spice extracts, oils and oleoresins are more consistent in flavor, do not have the potential to contribute microbial contamination, and they still contain the antioxidant properties. The addition of oils and oleoresins provide multiple functions in extending shelf-life of meat products. These ingredients have been shown to reduce color fading, provide flavor stability through antioxidant properties and as these ingredients are sterile and “cleaner,” the negative effect of spices on increasing microbiological growth is eliminated (Bacus, 1991).

Total level of added ingredients and injection level

USDA/FSIS regulates the amount of total ingredients that can be added to meat, as previously discussed. The industry utilizes injection level as a method to deliver the non-meat ingredients into the meat. The injection level has to be high enough so that an even distribution of the non-meat ingredients is obtained. If ingredients are not uniformly distributed, two-toned color or color variation within the lean surface and variation between bites within a sample for juiciness, tenderness and flavor will be identified.

A meat injector, either bone-in or boneless injector, utilizes needles to puncture into the meat and then a pressurized liquid solution is added. The level of addition of the added ingredients is controlled either through the speed of passage of the meat through the injector or by altering the pressure used during injection. Another important aspect of injection is the size and number of the needles. By increasing the number of needles and using smaller needles, injectors can deliver a more uniformly distributed injection solution into the final product. Uniform injection is of utmost concern, especially in a fresh pork product that is not going to be tumbled. One of the major quality defects is two-toned meat. As injection solutions have higher pH levels than the meat and increasing the pH results in darker colored lean, if larger and fewer needles are used to inject the product, the final product may appear two-toned. The pattern of the color variation in the lean follows the path of the needles.

A series of studies conducted at the University of Illinois showed that pork loin chops containing a 10% injection level and then either grilled or fried to internal cooked temperatures of 70 or 80°C had more pork flavor, were juicier, more tender, and had less off-flavors than chops from unpumped loins. Additionally, pumped pork loin chops had similar juiciness ratings regardless of the endpoint temperature that they were cooked; whereas, unpumped pork loin chops were drier as endpoint temperature increased. They also reported that pumped pork loin chops were lighter, redder, less yellow and had lower Warner-Bratzler shear force values. These results support the previous discussions that the addition of non-meat ingredients provides functionality that improves tenderness, juiciness, color and flavor of pork loins. They also examined the effect of pump level (0, 6, 12 and 18%) when used in pork loins that varied in pH. The purpose of this work was to understand if the addition of non-meat ingredients had greater benefits for meat from specific pH groups. The pork loin chops were evaluated after being cooked to 70 or 80°C. They found that as pump level increased, pump retention, package purge, retail purge, cook loss, salty flavors, and juiciness increased. However, pumping at any level increased tenderness and juiciness. They also reported that as meat pH increased, pump retention increased and package purge, retail purge and cook loss when chops were cooked to 80°C decreased. These studies indicate that enhancement or injection of non-meat ingredients adds functionality to pork products and that improvement in eating characteristics and color are found, however, as pump level exceeds 12% increased package and retail purge may be a concern.

Brewer et al. (2000) examined consumer acceptability for package purge, color, overall appearance acceptability, and purchase intent of vacuum-packaged, pumped pork loin roasts injected with 0, 6, 12 or 18% of a solution of .25% STP and 1% sodium chloride. Consumers rated the non-injected loin roasts as more desirable for color and texture appearance acceptability than the 18% injected loin roasts, but loin roasts injected with 6 and 12% pump levels were intermediate in acceptability and they were rated similar to the non-injected and 18% injected loin roasts. Overall appearance acceptability was highest for the non-injected pork loin roasts, but consumers rated the loin roasts injected with 6, 12, and 18% pump levels as only slightly less acceptable.

The effect of adding .25% SP, .5% sodium chloride and 2.5% sodium lactate in beef strip loin steak with injection level from 7.5, 10, 12.5 and 15% has been examined (Vote et al., 2000). They reported that when comparing the injected product to the non-injected controls, the injected beef strip loin steaks were juicier, more tender and had more intense cooked beef flavor, especially when steaks were cooked to higher degrees of doneness. In addition, as injection level increased, the steaks tended to be more tender and juicier, but flavor was not affected. Additionally, Warner-Bratzler shear force values decreased from 3.39 kg at the 7.5% injection level to 2.60 kg at the 15% injection level, but these differences were not statistically different. The lack of statistical difference for tenderness measurements was most likely due to the difficulty of controlling such fine differences of injection in a laboratory situation. Over time in a production situation, the differences they reported may be important.

References

Acuff, G.R. 1991. Organic acid prewashes – practical technologies to improve food safety. Proceedings of the Meat Industry Research Conference, American Meat Institute, Washington, DC, pg. 35.

Anders, R.J., J.G. Cerveny and A.L. Milkowski. 1989. Method of delaying Clostridium botulinum growth in fish and poultry. U.S. Patent, 4,798,729, Jan. 17.

Anwar, N., R.K. Miller, L.M. Lucia and G.R. Acuff. 2001. Potassium lactate and sodium diacetate use in beef top loin steaks. J. Food Sci. (In preparation).

Bacus, Jim. 1991. Antioxidants. Proceeding of the Meat Industry Research Conference, American Meat Institute, Washington, D.C.

Banks, W.T., C. Wang and M.S. Brewer. 1998. Sodium lactate/sodium tripolyphosphate combination effects on aerobic plate counts, pH and color of fresh pork Longissimus muscle. Meat Sci. 50:499.

Barbut, S., D.B. Josephson and A.J. Maurer, A.J. 1985. Antioxidant properties of rosemary oleoresin in turkey sausage. J. Food Sci. 50:1356.

Bishov, S.J.,Y. Masuoka and J.G. Kapsalis, J.G. 1977. Antioxidant effect of spices, herbs and protein hydrolyzates in freeze-dried model systems: Synergistic action with synthetic phonolic antioxidants. J. Food Process. Preserv. 1:153.

Brewer, M.S., F. McKeith, S.E. Martin, A.W. Dallmeir and J. Meyer. 1991. Sodium lactate effects on shelf-life, sensory, and physical characteristics of fresh pork sausage. J. Food Sci. 56:1176.

Brewer, M.S., J. Schlickau, C. Prestat, L.G. Zhu and F.K. McKeith. 2000. Consumer purchase intent and visual acceptabiloity of pumped pork loin roasts. Proc. 3rd Ann. Recip. Meat Conf., Columbus, OH, June 18-22.

Cannon, J.E., F.K. McKeith, S.E. Martin, J. Novakofski and T.R. Carr. 1993. Acceptability and shelf-life of marinated fresh and precooked pork. J. Food Sci. 58:1249.

Carpenter, J.A., R.L. Saffle and L.D. Kamstra. 1961. Tenderization of beef by a prerigor infusion of a chelating agent. Food Technol. 15:197.

Chang, S.S.,B. Ostric-Matijasevic, O.A.L. Hsieh and Huang, C.L. 1977. Natural antioxidant from rosemary and sage. J. Food Sci. 42:1102.

Cross, H.R., P.R. Durland and S.C. Seideman. 1986. Sensory qualities of meat. In Muscle as Food, P.J. Bechtel (Ed.). Academic Press, Inc. New York, NY.

Detienne, N.A. and L. Wicker. 1999. Sodium chloride and tripolyphosphate effects on physical and quality characteristics of injected pork loins. J. Food Sci. 64:1042.

De Wit, J.C. and F.M. Rombouts. 1990. Antimicrobial activity of sodium lactate. Food Micro. 7:113.

Debevere, J.M. 1989. The effect of sodium lactate on the shelf life of vacuum-packed coarse liver pate. Fleischwirtsch 69:223.

Eckert, L.A., J.V. Maca, R.K. Miller and G.R. Acuff. 1997. Sensory, microbial and chemical characteristics of fresh aerobically stored ground beef containing sodium lactate and sodium propionate. J. Food Sci. 62:429.

Egbert, W.R., D.L. Huffman, D.D. Bradford and W.R. Jones. 1992. Properties of low-fat ground beef containing potassium lactate during aerobic refrigerated storage. J. Food Sci. 57:1033.

Eilers, J.D., J.B. Morgan, A.M. Martin, R.K. Miller, D.S. Hale, G.R. Acuff and J.W. Savell. 1994. Evaluation of calcium chloride and lactic acid injection on chemical, microbiological and descriptive attributes of mature cow meat. Meat Sci. 38:443.

Evans, L.L. 1992. L-Sodium lactate in cooked beef top rounds: Differing levels of incroporation and cookery. M.S. thesis, Texas A&M University, College Station, TX.

Federal Register. 1982. Rules and Regulations Vol. 47, No. 49, 10763.

Federal Register. 1990. Sodium lactate and potassium lactate as flavor enhancers and flavoring agents in various meat and poultry products. Federal Register 55:7339.

Grau, F.H. 1980. Inhibition of the anaerobic growth of Brochothrix thermosphacta by lactic acid. Appl. Environ. Microbiol. 40:433/

Grones, K.L., R.K. Miller, L.M. Lucia and G.R. Acuff. 2001. Sodium lactate, sodium diacetate and soy protein concentrate addition to ground beef patties. J. Food Sci. (In preparation).

Houlihan, C.M., C.T. Ho and S.S. Chang. 1984. Elucidation of the chemical structure of a noel antioxidant, rosemaridiphenol, isolated from rosemary. J. Amer. Oil Chem. So. 61:1036.

Houlihan, C.M., C.T. Ho and S.S. Chang. 1985. The structure of rosmariquinone – A new antioxidant isolated from Rosmarinus officinalis L. J. Amer. Oil Chem. Soc. 62:96.

Johnsen, P.B. and G.V. Civelle. 1987. A standarization lexicon of meat WOF descriptors. J. Sensory Studies 1:99.

Jones, S.L., T.R. Carr and F.K. McKeith. 1987. Palatability and storage characteristics of precooked pork roasts. J. Food Sci. 52:279.

Keeton, J.T. 1983. Effects of fat and NaCl/phosphate levels on the chemical and sensory properties of pork patties. J. Food Sci. 48:878.

Krouse, R.J., H.W. Ockerman, B. Krol, P.C. Moerman and R.F. Plimpton. 1979. Influence of tumbling, tumbling time, trim and sodium tripolyphosphate on quality and yield of cured hams. J. Food Sci. 43:853.

Krol, B. 1972. Meat products. Voedingsmiddelentechnologie 3:157.

Lamkey, J.W., F.W. Leak, W.B. Tuley, D.D. Johnson and R.L. West. 1991. Assessment of sodium lactate addition to fresh pork sausage. J. Food Sci. 56:220.

Maas, M.R., K.A. Glass and M.P. Doyle. 1989. Sodium lactate delays toxin production by Clostridium botulinum in cook-in-bag turkey products. Appl. And Environ. Micro. 55:2226.

Maca, J.V., R.K. Miller and G.R. Acuff. 1997a. Microbiological, sensory and chemical characteristics of vacuum-packaged ground beef patties treated with salts of organic acids. J. Food Sci. 62:591.

Maca, J.V., R.K. Miller, M.E. Bigner, L.M. Lucia and G.R. Acuff. 1999. Sodium lactate and storage temperature effects on shelf life of vacuum packaged beef top rounds. Meat Sci. 53:23.

Maca, J.V., R.K. Miller, J.D. Maca and G.R. Acuff. 1997b. Microbiological, sensory and chemical characteristics of vacuum-packaged cooked beef top rounds treated with sodium lactate and sodium propionate. J. Food Sci. 62:586.

Mendonca, A.F., R.A. Molins, A.A. Kraft and H.W. Walker. 1989. Effects of potassium sorbate, sodium acetate, phosphates and sodium chloride alone or in combination on shelf life of vacuum-packaged pork chops. J. Food Sci. 54:302.

Miller, R.K. and G.R. Acuff. 1994. Sodium lactate affects pathogens in cooked beef. J. Food Sci. 59:15.

Molin, R.A., A.A. Kraft and D.G. Olson. 1985. Adaptation of a method for the determination of soluble orthophosphates in cooked and uncooked pork containing acid-labile poly- and pyrophosphates. J. Food Sci. 50:1482.

Moye, C.J. and A. Chambers. 1991. Poultry processing: An innovative technology for salmonella control and shelf life extension. Food Australia 43:246.

Offer, G. and J. Trinick. 1983. On the mechanism of water-holding in meat: The swelling and shrinking of myofibrils. Meat Sci. 8:245.

Pagach, D.A. 1992. The use of sodium and/or potassium lactate to extend shelf-life and reduce sodium leveles in precooked beef systems. M.S. thesis, Texas A&M University, College Station, TX.

Papadopoulos, L.S., R.K. Miller, G.R. Acuff, C. Vanderzant and H.R. Cross. 1991a. Effect of sodium lactate on microbial and chemical composition of cooked beef during storage. J. Food Sci. 56:341.

Papadopoulos, L.S., R.K. Miller, L.J. Ringer and H.R. Cross. 1991b. Sodium lactate effect on sensory characteristics, cooked meat color and chemical composition. J. Food Sci. 56:621.

Papadopoulos, L.S., R.K. Miller, G.R. Acuff, L.M. Lucia, C. Vanderzant and H.R. Cross. 1991c. Consumer and trained sensory comparisons of cooked beef top rounds treated with sodium lactate. J. Food Sci. 56:1141.

O’Connor, P.L., M.S. Brewer, F.K. McKeith, J.E. Novakofski and T.R. Carr. 1993. Sodium lactate/sodium chloride effects on sensory characteristics and shelf-life of fresh ground pork. J. Food Sci. 58:978.

Schlyter, J.H., K.A. Glass, J. Loeffelholz, A.J. Degnan and J.B. Luchansky. 1993. The effects of diacetate with nitrite, lactate, or pediocin on the viability of Listeria monocytogenes in turkey slurries. Int. J. food Microbiol. 19:271.

Sheard, P.R., G.R. Nute, R.I. Richardson, A. Perry and A.A. Taylor. 1999. Injection of water and polyphosphate into pork to improve juiciness and tenderness after cooking. Meat Sci. 51:371.

Shelef, L.A and L. Addala. 1994. Inhibition of Listeria monocytogenes by lactates in broth, chicken, and beef. J. Food Prot. 54:283.

Smith, L.A., S.L. Simmons, F.K. McKeith, P.J. Bechtel and P.L. Brady. 1984. Effects of sodium tripolyphosphate on physical and sensory properties of beef and pork roasts. J. Food Sci. 49:1636.

Sutton, D.S., M.S. Brewer and F.K. McKeith. 1997. Effects of sodium lactate and sodium phosphate on the physical and sensory characteristics of pumped pork loins. J. Muscle Foods 8:95.

Trout, G.R. 1989. Variation in myoglobin denaturation and color of cooked beef, pork, and turkey meat as influenced by pH, sodium chloride, sodium tripolyphosphate, and cooking temperature. J. Food Sci. 54:536.

Trout, G.R. and G.R. Schmidt. 1986. Effect of phosphates on the functional properties of restructured beef rolls: The role of pH, ionic strength, and phosphate type. J. Food Sci. 51:1416.

Vote, D.J., W.J. Platter, J.D. Tatum, G.R. Schmidt, K.E. Belk, G.C. Smith and N.C. Speer. 2000. Injection of beef strip loins with solutions containing sodium tripolyphosphate, sodium lactate and sodium chloride to enhance palatability. J. Anim. Sci. 78:952.

Watts, B.M. 1962. Meat products. In “Symposium on Foods: Lipids and Their Oxidation,” p. 202. H.W. Schultz, E.A. Day and R.O. Sinnhuber (Ed.). AVI Publishing Co., WeSPort, CN.

Weber, A.J. 1997. Palatability of roast beef and turkey injected with salts of various organic acids. M.S. thesis, Texas A&M University, College Station, TX

Summary of ingredient functionality where – = a negative effect, — = a very negative effect, — = an extremely negative effect, blank = a neutral effect, + = a positive effect, ++ = a very positive effect and +++ = an extremely positive effect.

Table 1. Summary of research to examine the relationship between level of sodium tripolyphosphate and meat yield.

Table 2. Summary of research to examine the relationship between level of sodium lactate and meat color, pH, TBA values and/or Aerobic Plate Counts. ND=Not determined as they were too numerous to count.

Table 3. Summary of research examining the effect of sodium lactate to aid in extending the shelf-life of meat products.

Table 4. Least squared means for treatment effects on meat color, TBA values, microbial levels and pH in enhanced beef strip loin steaks from Anwar et al. (2000). *P-value<0.05 from Analysis of Variance table; **P-value<0.01 from Analysis of Variance table; a dWithin a column and main effect with the same superscript are not different (P<0.05); eW=Water; PL=Potassium Lactate; NaDi=Sodium Diacetate; STP=Sodium tripolyphosphate; fScale for color where 1=extremely dark red, 8=extremely bright cherry red; gResidual Standard Deviation