Handling and Loadout of the Finisher Pig

Authors Jeff Hill, Premium Standard Farms Nick Berry, Iowa State University Anna K. Johnson, Iowa State University

Reviewers Mark Storlie, Iowa State University Renée Bergeron, Laval University

Introduction

Handling and movement is stressful for any size and type of pig, and even under the “best” conditions can cause significant changes in the pigs’ physiology, their behavior and consequently negatively impact pig performance and final meat quality.

Objectives

Identify direct costs to the U.S. industry from loss in performance, meat and personnel related handling issues. Discuss handling and loading process from the pigs’ perspective. Explore the relationship between the caretaker and the pig and the impact of selection and use of handling devices. Identify factors to assess on the farm to help ensure quality movement and handling of their finisher pigs.

Direct Costs to the Industry

Industry statistics reported for Dead on Arrival (DOA) at processing plants in 2004 was 0.23 % of pigs marketed, costing the U.S. swine industry $31,694,000. The incidence of Dead in Plant (DIP) was reported at 0.17 % or a loss of revenue at $23,770,500. Marketing and transportation stress does not only cost the industry due to mortalities but has direct impact on the quality of pork delivered to the consumer [1,7,13]. Problems with color have been estimated to cost $0.43 per head, for bruising, $0.08 per head and for pale, soft and exudative (PSE) meat, $0.90 per head. This results in a total lost opportunity for the U.S. swine industry of $254,104,500 or $2.44 per finisher head per year. These direct financial impacts represent only a small fraction of the true cost of marketing and pig transportation stress. There are a multitude of efficiencies that are lost, costs that are increased and risks endured.

One area that has been grossly overlooked in regards to the negative economical impact from poor handling and transport related issues is the cost to the employee. Over a third of the employee injuries within finishing operations are animal handling related of which a vast majority of these are due to the sorting and loadout procedures. In addition, the specialized practices necessary to ensure the well-being of the fatigued pig during unloading and within the processing facility are exhausting and physically challenging on plant personnel.

In addition, fatigued (also known as downers or non-ambulatory pigs) and deads disrupt standard animal flow resulting in reduced processing plant and transportation efficiencies. Fatigued pigs require specialized handling practices to ensure their well-being and such practices result in additional use of personnel time and labor, thereby reducing unloading efficiency at the processing facility.

To ensure the humane handling of these animals and to adhere to the Humane Slaughter Act, many processing facilities have devoted highly trained personnel to their lairage department, which has significantly increased lairage labor costs. Adding to this, the specialized equipment necessary to properly handle fatigued pigs requires significant investment in not only capital expenditures by the processing facility, but also increases the maintenance requirements.

The majority of processors are now not only charging the cost of a DOA animal back to the producer, but are also charging the cost for an animal received in a compromised state regardless of whether processed for consumption or rendered as a byproduct. In addition, many are also charging a handling fee to offset the extra labor cost, loss in efficiencies and liability associated with handling a compromised animal. These lost financial opportunities, additional costs, loss in efficiencies, and risk endured are all secondary to the ethical obligations and moral responsibilities we have to the animals under our care and to the consumers trusting the pork industry to produce, transport and process our animals in a humane and compassionate manner.

Handling and loadout: The Pigs’ Perspective

The pig: its behavior and basic anatomical features

To provide a safe and efficient system to handle pigs and load them properly it is of utmost importance to have a thorough understanding of their composition and physical attributes at marketing. In recent years pigs have been bred for increased muscle development, with today’s finisher pig weighing between 250-300 pounds, with a shoulder width of approximately 14 inches [26] and a total length exceeding 54 inches from snout to tail tip.

The way a pig behaves is dictated by the cues received from its environment utilizing its basic sensory capabilities. In brief, a pig has a wide peripheral vision of approximately 310 degrees, which provides a panoramic view of the world. However, of these 310 degrees, pigs have approximately a 12 degree field of best vision [14]. Like other animals, the pig does have a blind spot directly behind them and are only moderate judges of distance. Therefore people, changes in illumination intensities, moving objects, and contrast in color will result in animal hesitation and balking [12].

The auditory system of the pig has a range of frequency detection between 40 Hz and 40k Hz, which is slightly elevated compared to humans [15]. Loud, high pitched noises seem to be aversive to pigs [30], including high pitched vocalizations emitted by pigs experiencing traumatic events.Pigs have an acute sense of smell and as such use a wide range of olfactory cues in their behavior [5]. Finally, touch is detected through nerve endings in the skin and subcutaneous tissue, the snout is the primary organ of touch for the pig. However, through the foot pad the pig will identify changes in flooring texture and will hesitate at surfaces for which it is not accustomed.

In addition, pigs are social creatures that desire to remain in groups preferring to maintain visual, if not physical contact with their pen mates. If isolated pigs can become highly agitated, and the resulting excitement of the individual animal will negatively impact the behavior of an entire group which can certainly be detrimental during times of pig movement or loadout.

Additive stressor models: how does this relate to handling and load out?

In all methods of production, the pig is subjected to a constant barrage of internal and external stressors throughout its life. Stressors that impinge on an animal vary in time (i.e. frequency and duration), intensity (i.e. density an area), mode (i.e. visual, gustatory, emotional etc.,) and degree of novelty [3]. However, the body has developed physiological mechanisms to adapt with both short (acute) and chronic (long-term) stressors, that are neutral, negative or positive in regards to animal well-being. It is only when the stress level exceeds the body’s capacity to cope in a reasonable time frame that the pigs’ well-being is compromised. The inability to cope will result in loss of efficiency and long term harm with the ultimate extreme being death [17]. Novelty (i.e. handling, loading and mixing) can be a profound stressor to pigs [6,20,25], this is especially so when the novel experience is aversive. How an individual pig copes with such aversive stimuli can affect its overall performance and meat quality [4,10-12].

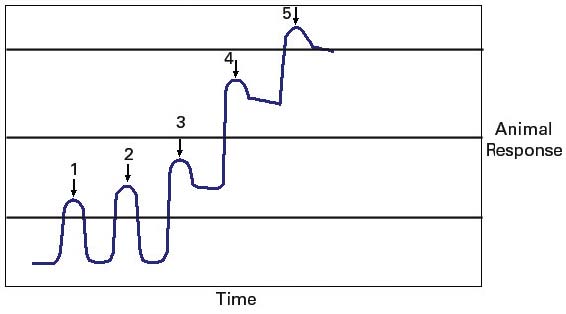

Figure 1. Adapted from Broom and Johnson [2]; Responses to a series of stimuli which, individually have moderate effects, but which can be lethal in combination. 1 = Movement from home pen along alley way, 2 = Electric prod use, 3 = Loading, 4 = Transport, 5 = Unloading.

The process of transportation can be visualized as “additive stressors” as proposed by McFarlane and Curtis [21], McFarlane et al., [22], and Broom and Johnson [2]. Over a given period of time, the pig is exposed to one stressor after another and the animal does not have time for its body to return to baseline. Each time a new stressor is added the stress response of the animal continues to become more intense. At some point, if the animal does not have time to recover, then the ultimate end-point can be death (Figure 1).

Handling and Loadout: The Pig and Caretaker Interaction

Caretaker

Caretakers can be your greatest asset or your greatest liability. Good animal handlers whom understand animal behavior, the production system and their impact on pork quality can minimize the impact of poor design. However, the best facility design can be rendered inadequate by poor animal handling. The basics of animal handling have been well defined and highly publicized in the swine industry, but it is becoming apparent that continual training and performance monitoring are necessary to maintain a high level of success.

Animal handling basics

Figure 2: Point of balance, blind spot and flight zone for a pig. Courtesy of Temple Grandin, 2006 [8].

An animal handlers’ primary objective is to minimize the animals’ level of fear and therefore their negative stress by maximizing positive interactions while encouraging the animal to move to the target location. This is accomplished by understanding the animals’ point of balance and how to manipulate the edge of the flight zone (Figure 2). For example, if you wish to move a pig forward you would need to stand behind the point of balance. Conversely, if you wish to back a pig up, standing in front of the point of balance will achieve the desired line of movement. Pigs can be moved simply by understanding and utilizing the point of balance without ever employing a moving aid.

Handling Devices

Ease of routine moving and handling of finisher pigs can be enhanced by an array of handling tools available to the producer [23,28]. The most common handling aids recommended by the swine industry to move finisher pigs include sort boards, large flags or plastic paddle sticks [27].

Recent work by McGlone et al., (2004) [23] compared a blue electric prod (1700 mA), with a paddle that had a plastic handle, a plastic board with no handle and a black flag on how effective they were to move finisher pigs. The data clearly demonstrated that while both the prod (~120 sec) and paddle (~125 sec) were effective in moving pigs the board was the most effective (~80 sec). Finally, the authors compared the board versus a flag and reported that there was no difference for pigs moved with either the flag (~60 sec) or board (~38 sec). The pigs seemed to view the board and flag as a solid impassable wall, unless they could see around the edges. If pigs observed an opening around the edges they attempted to exploit this by trying to pass through the hole.

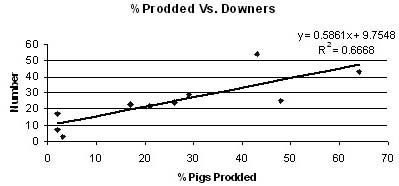

In comparison, it has been clearly demonstrated that the use of electric prods will increase the time required for movement, result in approximately 15% of the pigs to “jump” when the electric prod is applied, significantly increase vocalizations and cause a higher level of fatigued pigs received at the plant (Figure 3).

If regular use of an electric prod is needed, the adequacy of the handling facilities should be examined [8,9]. If a hog is prodded several times in rapid succession with an electric prod, its heart rate, body temperature,incidence of open mouth breathing and blood lactate levels will increase significantly, indicating that the pig is experiencing a stressor(s), which in turn can affect not only their well-being but also their meat quality [11].

Additionally, some work on previous experiences that pigs have with being handled (a term known as “walking the pens”) or let to roam outside the home pens for brief periods before load-out day can reduce the novelty and therefore the stress of the load-out experience [7,10]. Be warned, however, if pigs become too tame, they often will be more difficult than usual to move.

Figure 3: The impact of electric prod usage [24].

Caretaker attitude

The role of the stockperson in the well-being and productivity of farm animals has received increasing attention over recent years [6,17-19,29]. While some of the emphasis in this research has been placed on caretaker personality variables such as introversion, retroversion and neuroticism [29] the strongest predictors of caretaker behavior have been found to be in their attitudes [2,4,17]. Moreover, caretaker behavior has been shown to be strongly related to fear and reproductive performance in pigs [19] (Figure 4). It has also been proposed that empathy of the caretaker may be related to the well-being and productivity of animals under their care [6,17].

A group based in Australia has done extensive work on the role and empathy of the caretaker in relation to pig fear and its effects on performance. In one study, Hemsworth et al., (1994) [17] studied 25 commercial farms and compared a no training (control group) to a ‘‘attitudinal–behavioral modification’’ treatment which consisted of a cognitive–behavioral intervention procedure designed to modify the behavior of caretakers towards pigs. The effectiveness of the intervention program was assessed by monitoring the changes in the attitudinal and behavioral profiles of caretakers’ and the behavior and reproductive performance of pigs.

Results indicated that after training there were significant improvements in the attitude and behavior of the caretaker towards pigs, the behavioral response of pigs to humans and a trend towards improvement in pig reproductive performance. No such improvements were observed in the control treatment.

Figure 4: Caretaker-animal interaction. Coutesty of Hemsworth, 2003 [16].

How Can Swine Handling and Loading be Assessed on a Swine Farm to Ensure Well-Being?

To maintain a high level of success requires constant vigilance and evaluation of the system to identify areas for improvement. This requires a collaborative effort of the producer, transport company, and processing facility. At minimum, the factors that should be continuously monitored [31] are average live weight, load time (on a per pig basis), death loss (in transit and at the plant), non-ambulatory pigs and an identified reason for incurred loss (lame, fatigued, etc). Additional information including loading personnel, driver, trailer identification, prod usage, slips/falls percentage and chute integrity can be useful for continually improving the loading system.

Summary

More sound science needs to be funded in the area of loading and unloading of the finisher pig to help us understand how the pig perceives the environment, the caretaker – pig interaction and the importance of system design. The ultimate goal of sound research will be to provide pork producers with a tool that is practical and implementable on the farm. This will allow careful evaluation of handling and movement factors that may be either positive or detrimental to the well being of the pig. Ultimately, this will help improve the pigs overall well-being, thereby reducing both the direct and indirect costs that impinge on the profitability of the U.S. swine industry.

Literature Cited

1. Barton-Gade, P. 1992. Methods of assessing meat quality. Danish Meat Research Institute, Roskilde. Report No. 02.674/1.

2. Broom, D., and K. G. Johnson. 1993. Stress and animal welfare. Chapman and Hall, Oxford, UK.

3. Coleman, G. J., P. H. Hemsworth, M. Hay, and M. Cox. 2002. Modifying stockperson attitudes and behaviour towards pigs at a large commercial farm. Appl. Anim. Behav. Sci. 6:11-20.

4. Coleman G. J., P. H. Hemsworth, and M. Hay. 1998. Predicting stockperson behaviour towards pigs from attitudinal and job-related variables and empathy. Appl. Anim. Behav. Sci. 58: 63-75.

5. Curtis, S. E., S. A. Edwards, and H. W. Gonyou. 2001. Ethology and Psychology. In Pond W.G. and H.J. Mersman (ed). Biology of the Domestic Pig. Cornell University Press.

6. English, P. R. 1991. Stockmanship, empathy, and pig behaviour. Pig Vet. J. 26: 56–66.

7. Geverink, N. A., B. Engel, E. Lambooij, and V. M. Wiegant. 1996. Observations on behaviour and skin damage of slaughter pigs and treatment during lairage. Appl. Anim. Behav. Sci. 50:1-13.

8. Grandin, T. 2006. Home page. Available at http://www.grandin.com/. Accessed May 4, 2006.

9. Grandin. T. and M. J. Deesing. 1998. Behavioral genetics and animal science. Chapter One. Academic Press. San Diego, California. ISBH # 0-12295130-1.

10. Grandin, T. 1997. Assessment of stress during handling and transport. J. Anim. Sci. 75: 249-257.

11. Grandin, T. 1993. Livestock handling and transport. Ed T. Grandin, CAB Int.

12. Grandin, T. 1989. Behavioral Principles of Livestock Handling. The Prof. Anim. Sci. Vol. 5:2 (Abstr.).

13. Hambrecht, E., J. J. Eissen, D. J. Newman, C. H. M. Smits, L. A. den Hartog, and M. W. A. Verstegen. 2005. Negative effects of stress immediately before slaughter on pork quality are aggravated by suboptimal transport and lairage conditions. J. Anim. Sci. 83:440–448.

14. Heffner R. S., and H. E. Heffner. 1992. Visual factors in sound localization in mammals. J. Comp. Neurol. 317:219-232.

15. Heffner, R. S. and H. E. Heffner. 1990. Hearing in domestic pigs and gaos. Hear. Res.48:231-240.

16. Hemsworth, P. H. 2003. Human-animal interactions in livestock production. Appl. Anim. Behav. Sci. 81:185-198.

17. Hemsworth, P. H., G. J., Coleman, and J. L Barnett. 1994. Improving the attitude and behaviour of stockpeople towards pigs and the consequences on the behaviour and reproductive performance of commercial pigs. Appl. Anim. Behav. Sci. 39, 349–362.

18. Hemsworth, P. H., J. L. Barnett, and G. J. Coleman. 1993. The human–animal relationship in agriculture and its consequences for the animal. Anim. Welf. 2:33–51.

19. Hemsworth, P. H., J. L Barnett, G. J Coleman, and C. Hansen. 1989. A study of the relationships between the attitudinal and behavioural profiles of stockpersons and the level of fear of humans and reproductive performance of commercial pigs. Appl. Anim. Behav. Sci. 23, 301–314.

20. Knowles, T. G., and P. D. Warris. 2000. Stress physiology of animals during transport. In T. Grandin (ed.) Livestock handling and transport, 2nd edition. CAB Int.

21. McFarlane, J. M., and S. E. Curtis. 1989. Multiple concurrent stressors in chicks. 3. Effects on plasmas corticosterone and the heterophil: lymphocyte ratio. Poult. Sci. 68:522-533.

22. McFarlane, J. M., S. E. Curtis, R. D. Shanks, and S. G. Carmer. 1989a. Multiple concurrent stressors in chicks. 1. Effect on weight gain, feed intake and behavior. Poult. Sci. 68:501-509.

23. McGlone, J. J., R. L. McPherson, and D. L. Anderson. 2004. Case Study: Moving devise for finishing pigs: Efficacy of electric prod, board, paddle, or flag. Prof. Anim. Sci. 20:518-523.

24. McGlone, J. J. 2005. Inside the mind of the pig, Animal Care and Handling Conference. American Meats Institute (AMI). Kansas City, Kansas.

25. Moberg, C. P., and J. A. Mench. 2000. The Biology of Animal Stress. CAB Int.

26. Nabil, B. 1998. Determination of pig’s body dimensions by allometric equations measured by image analysis. Dept. of Animal Health and Welfare. Danish Institute of Agricultural Sciences.

27. National Pork Board. NPB. 2002. Swine Care Handbook. Accessed at www.pork.org on December 12th 2006

28. Ritter, M., M. Ellis, M. Benjamin, E. Berg, P. DuBois, J. Marchant-Forde, A. Green, P. Matzat, P. Mormede, T. Moyer, K. Pfalzgraf, M. Siemens, J. Sterle, T. Whiting, B. Wolter, and A. Johnson. 2005. The fatigued pig syndrome. J. Anim. Sci. 83(1):258.

29. Seabrook, M. F. 1972. A study of the influence of the cowman’s personality and job satisfaction on milk yield of dairy cows. Joint Conference of the British Society for Agriculture Labour Science and the Ergonomics Research Society, National College of Agricultural Engineering, UK, September.

30. Talling J. C., N. K. Waran, C. M. Wathes, and J. A. Lines. 1996. Behavioral and physiological responses of pigs to sound. Appl. Anim. Behav. Sci. 48:187-202.

31. TQA. Trucker Quality Assurance ProgramTM. 2002. National Pork Board. Accessed at www.pork.org on December 12th 2006 .