Contents

- 1.1 Storage Methods

- 1.2 Feeding Methods and Results

- 1.3 Other Factors to Consider When Using High-Moisture Grains

- 1.4 Storage/Feeding System

- 1.5 Summary

Originally published as PIH-73.

Authors:

Jerry Hawton, University of Minnesota;

Dave Bache, Purdue University;

Bruce McKenzie, Purdue University

Reviewers:

B. J. Caldwell, Forest, IN;

H. William Newland, Ohio State University;

Harold H. Hodson, Jr., Makanda, IL

Each year interest increases in storing high-moisture grain for livestock feeding. Originally, a shift toward more field shelling instead of picking ear corn may have brought this interest about because shelled corn must be mechanically dried in most instances for safe storage whereas ear corn can be safely stored at moisture contents up to 24% without drying. More recently, the concern has been in saving fuel. It takes approximately one gallon of propane fuel/41/2-6bu. and one kilowatt hour of electricity/10-12bu. With conventional high temperature drying to reduce the moisture content of wet grain ten percentage units (i.e., to dry from 25% down to 15% moisture). The prospect of fuel shortages and the near certainty of higher fuel costs plus the fact that many drying systems are pressed to keep pace with modern harvesting equipment are added reasons for interest in high-moisture grain. Also, with some cereal grains, earlier harvesting at higher moisture content results in reduced field losses and extra time to facilitate fall plowing in the north and seeding of a second crop further south.

Swine producers have centered their interest around highmoisture corn, sorghum (milo) and, to a much lesser extent, barley and wheat. High-moisture cereal grains can be successfully used in a swine feeding program. However, special consideration must be given to proper storage and feeding to realize maximum performance from its use.

Storage Methods

When ensiling high-moisture grain, you must store it in an oxygen-free environment to prevent spoilage. Proper ensiling or fermentation depends upon the percent of moisture in the grain. The ideal moisture content to ensile wet grain for swine appears to be in the 22-28% range. Moisture content over 28% leads to a greater fermentation, resulting in more acid production, which tends to be less palatable to the pig. On the other hand, the fermentation of grain containing less than 22% moisture is relatively slow, and the amount of acid produced may not be sufficient to kill those organisms that cause spoilage. This fact is especially true when oxygen (even in small amounts) can penetrate the grain mass. It should be pointed out, though, that type of storage has little effect upon spores or toxin already incorporated into the grain prior to storage.

There are three basic storage methods for high-moisture grains: (1) ensiling in sealed (airtight) storage, (2) ensiling in non-sealed storage, and (3) preservation with organic acid treatment. High-moisture cereal grains properly handled and stored using any one of these methods will provide a suitable swine feed.

Sealed Storage. High-moisture grain can be stored in specially constructed oxygen-limiting silos which operate by restricting the entry and exchange of air (oxygen is the important gas) into the storage. It is not necessary to crack or grind the grains before storing in this manner. Another characteristic of sealed storage is that it can be unloaded from the bottom. With whole shelled corn, the grain flows from the top surface into a funnel of withdrawal and down a center flow stream to the bottom outlet where it is usually augered to the outside.

Many hog producers invest in sealed storage (oxygenlimiting) facilities because they expect improvement in feed conversion and other performance measures. However, when compared on an equal dry matter basis, the data on highmoisture grains stored in sealed storage will not support claims of improved efficiency or growth rate in swine when compared with rations based on dry grains.

Sealed storage is the most popular method of storing highmoisture grains even though greater initial capital investment is required. This type of storage offers increased handling ease and reliability over non-sealed alternatives and eliminates the 2-5% spoilage loss normally associated with well-managed, unsealed systems.

Unsealed Storage. Unsealed high-moisture grain storage is commonly used for storing cattle feed and, to a much lesser extent, for swine feed. The grain should be ground into the storage unit to insure an adequate pack to exclude oxygen. The ideal particle size is similar to medium ground dry grain.

These ground materials must be unloaded from the top of the upright silos because they will not flow to a bottom withdrawal outlet. With unsealed storage such withdrawal should not be used anyway since it would destroy the pack, exposing the grain to oxygen and spoilage. About 3in. must be removed from the exposed surface per day during mild weather and greater amounts during warmer weather to prevent or control spoilage. Conventional upright silos made of concrete or steel that are in new or good condition are usually considered structurally adequate for wet grain storage if they are designed for grass silage storage. The silo structural adequacy should be checked with the manufacturer to insure a safe design; this is especially important in very large units. Silos to be used for wet grain storage should be equipped with a roof and tight door seals. It is wise to use a removable plastic top seal to reduce spoilage in the exposed top surface in the time between silo filling and feed out.

Horizontal silos can also be used for high-moisture grain storage, provided the material can be fed fast enough to control spoilage on the exposed surface. The grain should be well compacted and covered immediately after harvest. It is best to fill one end completely full to minimize surface exposure during filling. Even so, an increase in spoilage due to surface losses on the top and open face should be expected over conventional upright storage. Few horizontal silos are built or used solely for hog feeding with highmoisture grain.

Preservation with Organic Acid Treatment. Studies during the past ten years have shown that highmoisture grain, especially corn, can be treated with organic acid for storage up to one year without damage or loss of feeding quality for swine. When used correctly, these acid preservatives are not toxic to hogs and do not impair the palatability of the feed. They also offer little nutrient value. The cost per bushel to treat wet grain with an organic acid may run as much, or more, than the cost to dry it.

Several different organic acids have been used for preservation of high-moisture grain—acetic, propionic, isobutyric, formic, benzoic or combinations of these acids—but the most commonly used acids are propionic or propionic-acetic acid mixtures, marketed under various trade names. Studies involving use of anhydrous ammonia and other gaseous mixtures as a pre-storage treatment are currently underway but results are not complete.

If you plan to use an organic acid preservative, the high moisture grain should be treated as soon as possible after harvest, especially during warm weather. Rate of acid application varies with the moisture content of the grain and the intended length of storage. The higher the moisture content of the grain, the greater the amount of acid needed for proper preservation. Table 1 gives the recommended rates for 100% propionic acid for maximum storage periods of one year.

These rates are listed for corn but would be suitable for other grains. The acid application preserves the grain by inhibiting mold growth. The acid reduces the pH of the grain below the mold requirement and also kills the grain germ.

Acid preservatives are usually applied to the whole grain as it is conveyed into storage, generally as it moves through an auger equipped with a treater which sprays acid into the grain flow stream. The auger used during acid application should be flushed with water after each use to prevent corrosive damage. The major disadvantage of acid-treated grain is the corrosive effect the acids have on most types of metal in handling and storage equipment. The corrosion is usually most severe on surfaces in contact with the grain or vapor for the first several weeks following grain treatment. Corrosive damage to feed mills, self-feeders, and feed delivery augers may not be extensive since the bulk of the acid has been absorbed by the grain by the time it is removed for processing and feeding.

Acid-treated grain can be stored in any storage facility used for ordinary grain, with the limitation that the acid is very corrosive to steel, especially if galvanized. It may also react with concrete especially if newly cured and unweathered. It is recommended that all floors, walls, etc. be covered with polyethylene plastic, linseed oil, or acid-resistant paint before storing treated grains. Except for concern for nailhead corrosion, no special preparation is needed for wooden bins. Storage outdoors in uncovered piles may be practical in dry climates, but rain and warm weather can give severe spoilage problems in more humid areas. Such storage is not recommended for swine feed.

Acid-treated, high -moisture grain has essentially two advantages over ensiled grain: (1) it is not necessary to have sealed storage, and (2) the effectiveness of the acid treatment is maintained after the grain is removed from storage. These advantages allow for handling, transporting, mixing and holding time in feeders without heating and deterioration.

Feeding Methods and Results

Feeding methods and results for other high-moisture cereal grains used for feeding swine are essentially the same as for corn. Where differences occur, they will be explained at the end of the section.

High-moisture corn is, for all practical purposes, nutritionally equal to dry corn when compared on an equal dry matter basis. (To convert wet grain to a dry grain equivalent, divide the dry matter content of the wet grain by the dry matter content of the dry grain to establish an adjustment factor. Then multiply this adjustment factor times the weight of the highmoisture grain fed to obtain your answer). Essentially there are two basic feeding methods for high-moisture corn—freechoice feeding or in a complete mixed ration. Either method be stored at the point of feeding, power failure or equipment breakdown could pose some real problems if producers are not prepared to handle them. Consequently, good overall management of a highmoisture grain feeding system is extremely important.

It is also important to note that hogs are quite sensitive (from a palatability standpoint) to mold contamination of feeds. Also, some molds produce a substance with estrogenic activity which could cause pregnant females to abort or absorb their litters. High-moisture grain ensiled in either sealed or non-sealed storage is subject to spoilage shortly after removal from storage if the grain has not been previously treated with a preservative. Consequently this high-moisture grain should be fed on a daily basis (or several times a day) or at least no more than a 2-3 day supply should be placed in a self-feeder at one time. The spoilage can occur whether the grain is fed alone, top dressed with supplement, or fed as a complete mixed feed. Wet grains allowed to remain in conveyors of feeding systems for two or three days can also pose a problem. To prevent high-moisture grains from spoiling in the feeder, use the following guideline: When the temperature

is greater than 80°F, feed 2-3 times daily; from 40-80°F, feed daily; and when less than 40°F, you could feed every other day.

Free-Choice Feeding. For simplicity some swine producers favor the free-choice feeding method. It means feeding the high-moisture corn directly from storage in one self-feeder (or area) and the protein supplement in another, allowing the pig to make the decisions in regard to balancing its own diet. This method reduces the labor and expense of grinding or rolling rolling and mixing encountered with the complete mixed method.

Several university feeding studies using high-moisture corn and protein supplement free-choice for growing/ finishing swine indicate a slower rate of gain and a higher feed requirement per pound of gain when compared on an equivalent dry matter basis with a complete ground and mixed ration using dry corn. Similar results unfavorable to free-choice feeding were obtained when free-choice, high-moisture corn and protein supplement were compared with complete ground and mixed highmoisture corn rations. This inferior performance occurred whether the free-choice fed high-moisture corn was cracked, rolled, ground or shelled.

A likely explanation for the difference in performance is that high-moisture corn is often very palatable, leading to greater corn consumption and an inadequate intake of protein supplement. In other words, the pig may not properly balance its diet. Therefore, when choosing a protein supplement to be fed free-choice with high-moisture corn, the emphasis should be on its palatability. This means that the supplement should generally contain soybean meal as the only protein source or a mixture predominantly of soybean meal and only small quantities of less palatable feeds such as meat and bone meal, tankage and alfalfa meal. The operator must be alert and prepared to adjust supplement palatability. There have also been reports of overconsumption of protein supplement when fed free-choice with wet corn, even when less palatable feeds have been included. These reports further indicate the danger of depending on the pig to properly balance its diet.

Quality feeds (mold- and weevil-free, etc.) must be offered when fed in a free-choice feeding system or pigs will not readily accept them and, consequently, will consume more of the other free-choice component either the supplement or grain.

The free-choice feeding method may be used successfully if precautions are taken to insure proper intake of protein supplement relative to grain intake.

Complete Mixed Rations. Since most studies indicate an under- or overconsumption of protein supplement in free-choice feeding, it is recommended that either the high-moisture corn be included in a complete ground and mixed ration or mixed in the shelled form with a pelleted supplement.

When high-moisture corn is fed as recommended here, research shows that the performance of growingfinishing pigs is essentially equal to that of pigs fed complete ground and mixed rations using dry corn. This is true regardless of the high-moisture corn storage method. Research also reveals no apparent advantage in animal efficiency or performance from grinding, rolling or cracking high-moisture corn for growing-finishing pigs. However, it may be desirable to grind this corn to insure proper mixing with a ground or meal type protein supplement and to prevent pigs from sorting out the corn or supplement.

Spoilage may be a problem with a complete ground and mixed ration if the corn has not been previously treated with an acid preservative. Few problems should exist if careful attention is given to the daily amount of feed mixed and delivered. One popular feeding method is an automated system which mixes high-moisture shelled corn directly from sealed storage with a pelleted supplement. Both the corn and supplement are conveyed into a mixing hopper and then further conveyed into feeders or, if floor feeding is used, dropped several times a day. Another method delivers complete ground and mixed feed to self feeders, but the distribution system uses open conveyors that clean out after each use; and the feeders are loaded with only enough feed to last a limited time (usually one day).

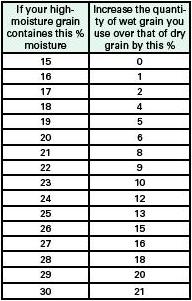

It will be necessary to make an adjustment in the formulation of complete mixed rations to compensate for the higher moisture content and thus maintain an equivalent nutrient intake. Table 2 shows a simple adjustment method. To use it, it is necessary to determine the corn moisture content. For example, if wet corn contains 25% moisture compared with 15% moisture for dry corn, Table 2 indicates that it will be necessary to increase the amount of wet corn by 13% to maintain equal nutrient and dry matter intake. Or, in other words, if for a ton of feed the mix is generally 1,650lbs. of dry corn (15% moisture) with 350lbs. of supplement, it now needs to be 1,864lbs. (1,650 x .13 = 214, then 1,650 + 214 = 1,864) of corn containing 25% moisture with the same amount of supplement.

Sorghum, Barley, and Wheat Feeding. If growing-finishing swine are fed sorghum (milo), barley, or wheat in the high-moisture form rather than the dry form, feeding method considerations and performance comparisons would be the same as for high-moisture/dry corn comparisons, with the following exceptions: (1) because of kernel hardness, it is necessary that high-moisture sorghum be ground or cracked when fed, (2) high-moisture barley should also be ground for best feeding results, (3) it is likely that a pig will be even more inconsistent in balancing its diet if high-moisture barley is fed with a protein supplement free-choice because it is not as palatable as high-moisture corn, (4) high-moisture wheat should be coarsely ground, and (5) a tendency toward depressed intake and gain has been reported when acid-treated wheat was fed.

Other Factors to Consider When Using High-Moisture Grains

Pigs less than 60Ibs. Pigs of this age and weight usually do not perform as well on high-moisture grain if free-choice feeding is used. However, if properly balanced, complete mixed, high-moisture grain rations are fed, satisfactory results should be expected even with pigs weighing as little as 15-20lbs.

Breeding herd. Never feed high-moisture grain to the breeding herd if you suspect any spoilage or mold contamination. In most operations, feeding the breeding herd may not adapt well to wet grain methods because the feeding locations are often scattered and the total quantities fed are comparatively small. Generally, high-moisture grain feeding programs are used for growing-finishing pigs.

Removal rate from unsealed storage. Producers using unsealed storage and non-acid-treated grain sometimes overlook the fact that it takes a considerable number of pigs consuming this high-moisture grain each day to stay ahead of spoilage. Approximately a 3in. depth of grain should be removed from the top of this type of storage in 70-75°F weather and 1in. or so more if warmer temperatures or above-normal humidity exists. To remove a 3in. depth from a 20ft. diameter silo would require approximately 700 pigs consuming 5lbs. per head daily.

Freezing. It is likely that grains containing 25% or more moisture will freeze and fail to feed down when placed in outdoor feeders in below-freezing temperatures.

Nutrient availability. There is evidence that carotene (vitamin A precursor) and vitamin E activity is reduced in acid-treated, high-moisture grains. Therefore, if such grains are to be fed to swine, vitamins A and E need to be provided in the diet at adequate levels. However, phosphorus is more available in high-moisture grain than in dry grain, regardless of preservation method. Even so, it is recommended that supplemental phosphorus be used in high-moisture grain diets to attain phosphorus levels equal to or only slightly below those stated as being adequate for normal grain diets. Since molds may produce an antimetabolite of vitamin K, it is advisable to make certain that vitamin K or menadione is added to high-moisture grain rations as a safety precaution.

Flexibility. High-moisture grain is limited to livestock feed and cannot be marketed in normal grain channels after undergoing fermentation or acid treatment. It can be marketed, however, to another livestock feeder either as wet grain or after drying.

When considering purchasing high-moisture grain to feed to swine, the buyer must establish his “bid” price. To do so, divide the dry matter content of the higher moisture grain by the dry matter content of the normal or dryer grain and multiply that factor by the price per bushel at which you can buy dry grain. Any additional handling costs such as drying or treating with acid should also be subtracted from this value to obtain a bid price for the high-moisture grain.

Example: When normal dry corn containing 87% dry matter is selling for $2.50 per bushel, what could you pay for a bushel of high-moisture corn containing 75% dry matter (or 25% moisture)?

Step 1. Divide the dry matter content of wet corn by the dry matter content of the dry corn to obtain an adjustment factor. 75% ÷ 87% = .86 (adjustment factor)

Step 2. Then multiply the price of a bushel of dry corn by the adjustment factor to obtain a price for wet corn. $2.50 x .86 = $2.1 5 (wet corn price/bushel)

Step 3. Subtract any additional per bushel handling cost for the wet corn (over and above that of handling dry corn) from the $2.15 value to obtain a bid price for the high-moisture corn.

Storage/Feeding System

Cost Comparisons of Alternative Systems A producer’s decision whether or not to go with a high moisture grain feeding system for swine should be based primarily upon economic and operational rather than nutritional differences. Good swine producers can take a number of different corn-hog system combinations and make them work profitably.

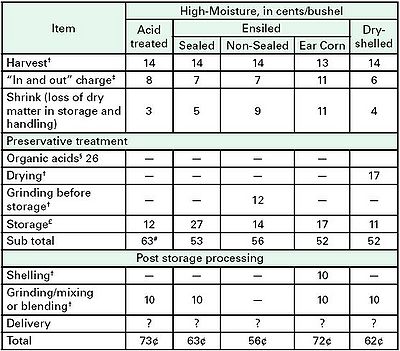

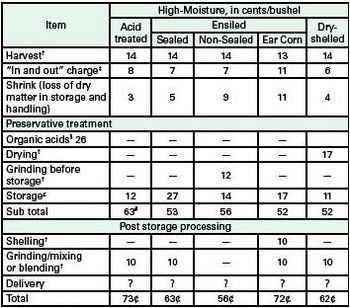

Following are comparisons of the costs of alternative corn handling/storage/feeding systems, along with a brief discussion of each to help evaluate some of its pros and cons. Table 3 contains the best current estimates of the cost consequences of choosing one method of corn preservation over another. However, realizing that each farm situation is different, a feature which may appear as an advantage to one operator may be a disadvantage to another.

Harvest. Much more important than the small variation between systems in harvesting cost per bushel are the implications for field losses in harvest because of timeliness. Dried corn systems permit a considerable range in the moisture content at which corn may be harvested, thus lengthening the harvest season. A disadvantage, however, is that the dryer often forms a bottleneck in the system, thus restricting harvesting speed. High-moisture systems eliminate that bottleneck but may shorten the season, since high-moisture corn for hogs makes the best feed at moisture contents of 22-28%.

“In and Out” Charge. The figures in Table 3 differ between systems to reflect a variation (1) in volume of material to be moved, (2) in the ease with which material flows and (3) in its corrosiveness. For example, ear-corn may present some flow problems, and the volume of material is doubled.

Shrink. Loss should be least for the acid-treated corn since you get prompt mold-killing action as well as a stoppage of seed respiration. You get the same action in ensiling, but it develops over a period of time as bacteria manufacture organic acids and use up the oxygen in the storage structure. We have imposed a penalty, though modest, against the ear-corn system and the unsealed silo because of the vulnerability of the stored grain to rodents, weather damage and spoilage.

Organic Acid Cost. Application of the acid treatment requires precision equipment which will cost approximately $650. While cost of acid may vary depending upon location, a cost of 45¢/lb. seems to best reflect present commercial prices. To establish a charge for acid preservation in Table 3, the acid application rate is listed at 20lb/ton (or 1% by weight) for long term (1 year) storage. Lesser amounts of acid could be used for shorter storage periods (6 months or less) but should not be reduced by more than one-half of the amounts suggested in Table 1.

Drying. The drying charge in Table 3 is based on the removal of 10 percentage points of moisture. Approximately half the charge represents fuel and power; the other half is the cost of owning drying equipment.

Storage. The figures in Table 3 are an estimate of the cost of owning the various structures. Ear-corn structures tend to be relatively inexpensive per unit of capacity, but take twice as much volume when you store the cob. If snow fence or other lowerinvestment structures are used, the storage cost is reduced but “shrink” charge is increased. It is assumed that acid-treated corn will be stored in round metal bins that have received a protective coating to prevent corrosion. In spite of such treatment, there have been cases where corrosion has cut structure life in half. However, the assumption in Table 3 is that structures will have a normal life storing acid-treated corn. Acidtreated corn storage in open areas would reduce the storage cost in Table 3, but would result in inefficient handling and greater shrink because of bird and rodent damage.

Sub-total. Table 3 indicates a sub-total of costs because there will be great variation between farms in the treatment that corn receives after being taken from storage. The interesting aspect of the sub-total is that three of the five systems have estimated costs that are practically identical. High-moisture, unsealed, is a bit higher because grinding takes place before rather than after storage. And acid treatment for long term storage adds about 10¢ per bushel to costs.

Shelling. Ear corn will be shelled when it comes out of storage unless that function is turned over to the hogs. The freechoicing of ear corn and supplement is a well-tested production technique. The system requires considerable management skill to insure that hogs are eating enough supplement to balance their ration and that corn is not being wasted. The feeding of ear corn is not common under close confinement and does not fit with modern slatted-floor, liquid-manure production systems.’

Grinding. Wet shelled corn that is ensiled in non-sealed storage requires grinding into storage to improve compaction. Since “before storage” grinding will require high volume equipment, it will likely be more costly than the lower volume grinding out of storage. Dried corn is usually most successfully fed after grinding. However, the grinding function is often left out of ear corn, acid-treated, and sealed-ensiled systems. Elimination of grinding saves 10-12 cents per bushel but introduces the penalty of a loss of control over the ration. A ground and mixed ration places the producer, rather than the hog, in charge of nutrition.

Delivery. There are significant differences between systems in the cost of delivering grain from storage to the hogs. Most of the available equipment has been designed for dry feed. Most self-feeders, grinder-blender devices, pneumatic distribution systems, and closed conveyor distribution units have been designed for and work well with dry feed. Some can cause serious problems with high-moisture grain. Acid-treated grain poses the added dimension of corrosiveness. And, if the grain has not been treated with organic acids, high-moisture systems must be designed so that they empty, leaving minimal residues to spoil and clog in conveyors and feeders. This fact implies: (1) “U” troughs as opposed to closed augers, (2) manual control of the level of feed in the hog feeders as opposed to pressure switches, and (3) greater need for a readyto-go, high reliability system since very little feed can be stored at the point of use.

Conclusions. The low cost system in Table 3—Ensiled in Non-Sealed Storage—has the disadvantages of: (1) involving considerable risk of spoilage or quality loss and of (2) requiring constant, alert supervision of the storage and feeding activities.

The high cost systems—Ear Corn and Acid-Treated High-Moisture Corn—probably are adapted to small enterprises and/or as emergency or temporary procedures.

In most situations, the competitive systems will be Ensiled in Sealed Storage and Dry Shelled. In this competition, Dry Shelled has the advantages of flexibility, ease of management and the availability of proven, automated systems for handling feed after it has left storage. The Wet Grain Sealed system has t he advantage of no drying bottleneck, low energy costs and higher product palatability. The Dry Shelled System has the disadvantage of requiring fuel for drying. Fuel costs are likely to rise faster than the costs of other inputs in the years ahead. The wet grain system has the disadvantage of tending to require special distribution and feeding equipment, and frequent adjustment to control dry matter intake. It also has an added risk of feed spoilage.

Summary

- High-moisture grains properly ensiled in sealed or nonsealed storage or preserved with an organic acid are suitable swine feeds. But no one should convert to high-moisture grains expecting to improve feed efficiency or growth performance.

- Even though a higher initial capital investment is required, sealed storage is a more popular method of storing high-moisture grains than unsealed storage because there is greater control over the grain and less loss because of spoilage.

- High-moisture grain removed from either sealed or unsealed storage is subject to rapid spoilage, especially in warm weather. Automated feeding equipment and careful attention given to the daily amount of feed mixed, distributed and consumed can give good performance.

- Storage of acid-treated grain permits use of less expensive storage facilities than that for ensiling grain, and there is little danger of the grain spoiling shortly after removal from storage. However, it may cost as much or more to treat the grain with an organic acid than it does to dry it. Also, the acid from the treated grain may cause corrosion in feed handling and storage equipment.

- Rate of gain and feed efficiency, when compared on an equal dry matter basis, have been essentially the same for pigs fed high-moisture or dry grains when the grain and supplement have been mixed together rather than fed free-choice.

- Free-choice feeding of high-moisture grain may be used successfully if proper intake of protein supplement relative to grain intake is assured. Free-choice feeding is not recommended for pigs under 60lb.

- Since slower rate of gain and higher feed requirement per pound of gain usually result with the freechoice feeding system, it is recommended that the high-moisture grain should either be mixed with a pelleted supplement or included in a complete ground and mixed ration.

- The amount of high-moisture grain used in a complete mixed ration will have to be corrected to compensate for the higher moisture content compared to using dry grain.

- There is no apparent advantage to grinding or cracking high-moisture corn for growing-finishing pigs other than for mixing purposes. However, grinding or cracking increases the feeding value of high-moisture sorghum (milo), barley and wheat.

- The possible use of high-moisture grain in a swine feeding program is primarily an economic and operational rather than a nutritional decision. Therefore, the various costs involved should be carefully examined.

Table 1. Amount of 100% propionic acid required for 1 year of storage. The amounts of acid listed are for long term storage (1 year). For storage periods of 6 months or less, the amount of acid used could be reduced by one half. †56lb. of high-moisture corn.

Table 2. Moisture adjustment table for replacing dry grain with high moisture grain.

Table 3. Estimate of comparative costs per bushel for harvesting, storing, processing and feeding corn preserved in various ways. This is not a complete list of the cost of harvesting, storing and processing corn—only of those costs affected by method of preservation. (For instance, interest on the money invested in stored grain is ignored.) †These cost estimates are based on the rates charged by custom operators in the midwest in 1979. ‡Estimated cost of moving material in and out of storage includes ownership cost for legs, blowers, and augers. §Assumes 20,000bu. to be acid-treated yearly; applicator cost $650.00 and depreciated over 5 years; organic acid costs 45¢/lb. and is applied at the rate of 20Ib/ton of grain. £Assumes a 20-year life on storage structure. Sealed high-moisture storage costs $2.00/bu.; unsealed, $1.00/bu.; dry corn storage 80¢/bu., ear corn storage $1.25/bu.; protective coating to prepare metal bins for storage of acid-treated corn adds 10¢/bu. to storage investment. #If acid is applied at half the Table 1 recommendation for a short storage period, this system is also comparable in cost to the other lower cost systems.