Contents

- 1.1 Introduction

- 1.2 Gases Used in MAP of Meat

- 1.3 Meat Color

- 1.4 Meat Microbial Spoilage

- 1.5 Meat Microbial Safety

- 1.6 Safe Shelf Life Prediction

- 1.7 Conclusions

- 1.8 References

Originally published as a National Pork Board/American Meat Science Association Fact Sheet.

Authors:

Harshavardhan Thippareddi, University of Nebraska;

Randall K. Phebus, Kansas State University

Reviewer:

Melvin Hunt, Kansas State University

Introduction

Manipulation of the food product microenvironment using combinations of gaseous atmospheres has been in practice since the early 1930s. Developments in packaging materials and technologies have made the application of modified atmosphere packaging (MAP) on a larger scale to meat and meat products feasible (Brody, 1989).

Packaging a perishable product in an atmosphere which has been modified so that its composition is other than that of air is termed as MAP (Hintlain and Hotchkiss, 1986). In contrast, controlled atmosphere storage (CAS) involves maintaining a precisely defined atmosphere in the storage chamber by continuous monitoring and compensating for atmospheric changes due to product /microbial respiration or package permeability.

The main purposes of MAP of meat and meat products is two fold: to ensure the (i) microbiological shelf life and (ii) the sensory quality of the product, including the color, odor and palatability. Conversion of meat animals to meat invariably results in contamination of the previously sterile muscle interior with spoilage flora and pathogenic species. The microorganisms causing spoilage often out-compete pathogenic organisms and limit the storage life of the products due to production of undesirable colors and odors. Thus, technologies that provide extension of shelf life of the product, both sensory and microbiological, without compromising their safety are being sought. MAP addresses both these objectives, by using combinations of gases in the product environment that limit or reduce growth of spoilage and pathogenic microflora of meat and stabilize the color of the meat.

Gases Used in MAP of Meat

Carbon dioxide, oxygen and nitrogen are the commonly used gases in MAP, along with trace amounts of carbon monoxide, argon and helium. Each of these gases has specific properties and functions and influences the shelf life (microbial and sensory) of the MAP of meat and meat products. In most cases, combinations of these gases are used to minimize the microbial spoilage and improve the color and other sensory characteristics.

Oxygen

The concentration of oxygen in the package determines the oxidative state of the myoglobin in fresh meats (Fig. 1) and the microbiological shelf life of the product. Traditionally, for fresh meats, oxygen concentrations greater than 5% are required to create the desired bright red color (Holland, 1980), while concentrations less than 2% will result in brown color due to metmyoglobin formation (Seideman and Durland, 1984).

Carbon dioxide

The bacteriostatic and fungistatic properties of carbon dioxide have been widely recognized since the 1920s and was used in shipments of beef, mutton and lamb from Australia and New Zealand to England. Carbon dioxide is highly soluble in water, and its’ solubility increases with decreasing temperature and higher meat pH. Greater than 99% of the gaseous carbon dioxide exists as dissolved gas and less than 1% as carbonic acid (H2CO3), which partially dissociates to give H+, HCO3- and CO3 2-. Although drop in surface pH of meat due to dissolution of CO2 in meat does not fully explain the bacteriostatic effects of CO2, it does contribute significantly to its antimicrobial activity. At lower product temperatures, the solubility of CO2 is greater, and hence is more effective in retarding microbial growth. Thus, CO2 in the product atmosphere in combination with strict temperature control will improve the microbiological quality of the product.

Although older literature indicates that CO2 concentrations greater than 20% result in undesirable brown color in muscle and bone due to either formation of metmyoglobin or precipitation of sarcoplasmic proteins (Seideman and Durland, 1984), this probably was due to small amounts of residual oxygen.

Nitrogen

Nitrogen is normally used as inert filler, and to prevent package collapse when carbon dioxide dissolves into meat tissue (Lambert et al., 1991). While some studies reported extension of shelf life by nitrogen, others did not indicate any antimicrobial/bacteriostatic activity. The variability in shelf life extensions observed in some of the studies could be due to the residual oxygen concentrations in the MAP products due to incomplete evacuation of air from the packages. Thus, inclusion of nitrogen in MAP atmospheres should provide an advantage in terms of exclusion of oxygen and thus, in preventing aerobic spoilage microflora in the meat products.

Carbon monoxide

CO can be used as part of the MAP gaseous mixtures, ranging from 0.3-0.5 %, for stabilization of fresh meat color. Carbon monoxide (CO) has been approved by FDA (2002) for use as a component of a gas mixture in a MAP system as Generally Recognized as Safe (GRAS) up to 0.4%. Although use CO as part of the gaseous mixture of MAP packaged meats has been limited in the United States due to its toxicological effects, the GRAS status should provide the impetus to its’ increased use. In Norway, MAP of meats using mixtures of carbon monoxide has an estimated 50-60% of the retail market share. Carbon monoxide extends the lag phase and slows growth rate of E. coli, Achromobacter and P. fluorescence (Gee and Brown, 1981) at concentrations of 25-30%, while P. aeruginosa is unaffected even at these high concentrations. However, the use of carbon monoxide at the low concentrations normally recommended (1%) would have relatively little effect on bacterial growth on fresh meats (Hunt et al., 2002).

Combinations of carbon monoxide with other gases such as carbon dioxide to control microbial growth provide an excellent opportunity for meat processors to improve shelf lives of the retail packed fresh meats (Kropf, 1980). With an increasing trend towards case-ready meats, carbon monoxide can provide the means to achieve the retail display life of fresh meats for today’s industry.

Meat Color

Meat color is the single greatest appearance factor that determines whether or not a meat cut will be purchased (Kropf, 1980). The color of muscle tissue is determined by the concentration of oxygen (Fig. 1) and the oxidation state of the muscle pigment, myoglobin (Fig. 2). The display life of meat is limited by the time required for oxidation of oxymyoglobin to metmyoglobin, initially on the surface layers of muscle tissue, and reaches proportions of total pigment concentrations that the meat appears dull, and eventually brown (Gill, 1995).

During normal distribution of meat products, the primals and sub-primals are marketed to the retailers vacuum packaged, and the retailer fabricates these into smaller retail cuts, and displays them in overwrapped packages. The myoglobin, normally will be in deoxy- form under vacuum and is converted to oxyform during fabrication and display. The oxymyoglobin is gradually oxidized to form metmyoglobin, and the kinetics of the process is dictated by several factors such as the muscle type, rate of postmortem pH decline, packaging film, oxygen consumption, display lighting and temperature and the intrinsic metmyoglobin reducing activity of the muscle (Ledward, 1985).

Exposure of pork and pork products to nitrogen in the gaseous environment does not affect the color, and is similar to vacuum packaged products. Presence of carbon dioxide in the MAP gas mixture has been reported to discolor meat. However, this is likely due to presence of small amounts of residual oxygen in the package as metmyoglobin formation is independent of carbon dioxide concentration (Ordonez and Ledward, 1977). Thus, removal of essentially all of the oxygen from the package is essential to delay or prevent discoloration (Jeremiah, 2001).

Oxygen in the environment is necessary to impart the fresh meat color by formation of oxymyoglobin, which is more resistant to oxidation, compared to the deoxy form. The presence of minimal concentrations of oxygen would suffice for the growth of aerobic spoilage flora of meat, and their growth can be delayed by incorporation of 20 to 30% carbon dioxide in the gas mixtures (Gill, 1995).

Incorporation of carbon monoxide in the gas mixture can provide a stable, cherry red color to the meat by formation of carboxy myoglobin, which is more resistant to oxidation compared to the oxymyoglobin (Sorheim et al., 1997). As discussed earlier, combination of carbon monoxide with other gases can provide the advantages of color stability in addition to microbial control.

Meat Microbial Spoilage

Fresh meats provide a rich source of nutrients and support microbial growth (Gill and Newton, 1977). Presence of aerobic conditions (non-limiting in oxygen concentrations) results in growth of mainly aerobic psychrotrophic types, Acinetobacter, Moraxella and Pseudomonas. Growth of Pseudomonas results in production of mal-odors, putrid compounds when the available energy source (glucose) is depleted and the amino acids are utilized for energy requirements (Gill, 1976 and Gill and Newton, 1978). In the absence of oxygen, the aerobic spoilage types are inhibited and spoilage is primarily due to anaerobic, aerotolerant lactobacilli. In normal meat (pH<5.8), the lactobacilli predominate and produce delayed acid-dairy flavor to the meat subsequent to growth to very high populations (Seideman and Durland, 1983). However, in high pH (>5.8) meats, the facultative anaerobic types, psychrotrophic Enterobacter, Brochothrix thermospachta, and Alteromonas putrifaciens will predominate. While Brochothrix imparts a sour odor, growth of Enterobacter and Alteromonas will result in putrid, sulfurous odors at higher populations.

The microbial spoilage of fresh meats is dictated by the initial microbial quality of the meats, types of organisms present initially, product storage temperature, time and package conditions, including the gaseous atmospheres in the MAP products. It should be borne in mind that evacuation and incorporation of a particular mix of gases does not assure maintenance of the concentrations indefinitely, and respiration of muscle as well as the surface microflora will modify the atmospheres in the MAP products. Thus, the levels and types of microflora will be dynamic, depending on the prevailing atmospheres and their lengths of time.

Meat Microbial Safety

The majority of MAP fresh meats are stored refrigerated, and hence pathogens that can survive and grow under these conditions, such as Listeria monocytogenes, Yersinia enterocolitica, Aeromonas hydrophila, Bacillus cereus and Clostridium botulinum will be discussed.

L. monocytogenes has emerged as a pathogen of concern to the meat industry since the 1990s. The organism is psychrotrophic, facultatively anaerobic, and widely distributed in the environment. In spite of its ability to grow under refrigerated temperatures, the organism does not compete well with the normal spoilage flora of meat (Manu-Tawiah et al., 1993). At high concentrations of carbon dioxide (100%), L. monocytogenes does not grow even in high pH fresh meat at < 5°C; however, presence of very low levels of oxygen (5%, Gill and Reichel, 1989) or vacuum packaging and storage at 0, 5 or 10°C does allow its growth. Further, L. monocytogenes did not grow in MA (75% CO2 and 25% N2) in poultry meat, indicating that a combination of carbon dioxide at high concentrations and low storage temperature can control this pathogen.

Yersinia enterocolitica is more prevalent in pork and pork products, is a facultative anaerobe and can grow at refrigeration temperatures (psychrotrophic). Y. enterocolitica can grow (at 4°C) on fresh pork chops, and its growth rate is enhanced in anaerobic/CO2 enriched conditions, and is similar to the spoilage microflora, reaching very high population levels within 35 days of storage. Thus, the presence of this pathogen on fresh meat can result in growth and may reach substantial populations to present a microbiological risk when stored under vacuum or MAP.

Aeromonas hydrophila is a psychrotrophic, facultative anaerobe, although rarely isolated from fresh pork and pork products, can pose a microbiological safety risk. A. hydrophila can grow on high pH meat in vacuum, while in CO2 enriched atmospheres, its growth is inhibited (Gill and Reichel, 1989). The fact that the organism can survive in pork stored under N2 for 10 days at 4°C, but not under carbon dioxide, indicates that the organism is sensitive to carbon dioxide at low temperatures. Storage of pork loin slices at 1°C under MAP increased the shelf life to >16 days, along with control of A. hydrophila, while a 7 day shelf life was observed for slices packaged in air (Mano et al., 2000).

Bacillus cereus is a spore former, and although the majority of the isolates are mesophilic, some psychrotrophic strains have been reported. Effects of MAP gases on germination and growth of this pathogen in fresh meats have not been investigated.

Clostridium botulinum belonging to group II (non-proteolytic) can grow under refrigerated, anaerobic conditions. Use of carbon dioxide concentrations >45% may provide a degree of safety in terms of delaying C. botulinum toxigenesis. The incidence of psychrotrophic C. botulinum is rare in pork and pork products, and strict temperature control at 1°C can reduce the risk of its growth and toxigenesis.

Safe Shelf Life Prediction

In a logical extension of predictive modeling, Labuza et al. (1992) described a method to determine the shelf life of MAP meat products taking into consideration the microbial spoilage, microbiological safety and the visual/sensory deterioration of the food products. During development of a new product or application of a new packaging system for existing product, such as MAP, it is necessary to evaluate the microbiological risks scientifically, and determine the safe shelf life of the product.

In MAP products, where higher concentrations of carbon dioxide are used to control spoilage flora, and carbon monoxide is incorporated into the gas mixtures to prevent or reduce the organoleptic/visual spoilage, extreme care must be taken in determining the safe shelf life of the product and strict adherence to the sell-by/use-by dating procedures should be followed to prevent microbiological risks.

Conclusions

Although the use of MAP in meat and meat products has been practiced for almost a century in Australia/ New Zealand and Europe, the potential incentives that can be achieved using this technology has not been realized in North America. However, caution should be exercised in determining the optimal combinations of the gas mixtures, with strict adherence to temperature control and comprehensive evaluation of safety of the product should be conducted prior to introducing these products in the market.

References

Brody, A. L. 1989. Modified atmosphere/vacuum packaging of meat. In Controlled/Modified atmosphere/Vacuum packaging of foods. Ed. A. L. Brody. Food and Nutrition Press, Inc., Trumbull, CT, U.S.A. pp. 17-38.

FDA. 2002. Agency Response Letter: GRAS Notice No. GRN 000083. http://www.cfsan.fda.gov/~rdb/opa-g083.html

Gee, D. L. and W. D. Brown. 1981. The effect of carbon monoxide on bacterial growth. Meat Sci. 5: 215-222.

Gill, C. O. 1976. Substrate limitation of bacterial growth at meat surfaces. J. Appl. Bacteriol. 41: 401-410.

Gill, C. O. 1995. MAP and CAP of fresh, red meats, poultry and offals. In Principles of modified atmosphere and sous vide product packaging. Ed. J. M. Farber and K. L. Dodds. Technomic Publ. Co. Lancaster, PA. U. S. A. pp. 263-324.

Gill, C. O. and K. G. Newton. 1977. The development of aerobic spoilage flora on meat stored at chill temperatures. Meat Sci. 33: 1284-1286.

Gill, C. O. and K. G. Newton. 1978. The ecology of bacterial spoilage of fresh meat at chill temperatures. Meat Sci. 2: 207-217.

Gill, C. O. and M. P. Reichel. 1989. Growth of the cold tolerant pathogens Yersinia enterocolitica, Aeromonas hydrophila and Listeria monocytogenes on high pH beef packaged under vacuum or carbon dioxide. Food Microbiol. 6: 223-230.

Hintlain, C. B. and J. H. Hotchkiss. 1986. The safety of modified atmosphere packaging:A review. Food Technol. 40(12): 70-76.

Hunt, M. C. 2002. Personal Communication.

Hunt, M. C., K. A. Hachmeister, D. H. Kropf, M. Merriman and G. Del Duca. 2002. Carbon monoxide in MAP of beef steaks and ground beef: effects for color, shelf life and microbiology. Proc. 55th Reciprocal Meat Conf., Amer. Meat Science Assoc. 55:

Jeremiah, L. E. 2001. Packaging alternatives to deliver fresh meats using short- or long- term distribution. Food Res. Intl. 34: 749-772.

Jones, M. V. 1989. Modified atmospheres. In Mechanisms of action of food preservation procedures. Ed. G. W. Gould. Elsevier Applied Science, Essex, England. Pp. 247-284.

Kropf, D. H. 1980. Effect of retail display conditions on meat color. In Proc. Reciprocal Meat Conf. 33: 15-32.

Labuza, T. P., B. Fu and P. S. Taoukis. 1992. Prediction of shelf life and safety of minimally processed CAP/MAP chilled foods. A review. J. Food Prot. 55: 741-750.

Lambert, A. L., J. P. Smith and K. L. Dodds. 1991. Shelf life extension and microbiological safety of fresh meat: A review. Food Microbiol. 8: 267-297.

Lanier, T. C., J. A. Carpenter, R. T. Toledo and J. O. Reagan. 1978. Metmyoglobin reduction in beef as affected by aerobic, anaerobic and carbon monoxide containing environments. J. Food Sci. 43: 1788-1792.

Ledward, D. A. 1985. Post slaughter influences on the formation of metmyoglobin in beef muscle. Meat Sci. 15: 149-171.

Manu-Tawiah, W., D. J. Myers, D. G. Olson and R. A. Molins. 1993. Survival and growth of Listeria monocytogenes and Yersinia enterocolitica in pork chops packaged under modified gas atmospheres. J. Food Sci. 58: 475-479.

Ordonez, J. A. and D. A. Ledward, 1977. Lipid and myoglobin oxidation in pork stored in oxygen and carbon dioxide enriched atmospheres. Meat Sci.1: 41-49.

Seideman, S. C. and P. R. Durland. 1983. Vacuum packaging of fresh meat: A review. J. Food Qual. 6: 29-47.

Sorheim, O., H. Nissen and T. Nesbakken. 1999. The storage life of beef and pork packaged in an atmosphere with low carbon monoxide and high carbon dioxide. Meat Sci. 52: 157-164.

Sorheim, O., T. Aune and T. Nesbakken. 1997. Technological, hygienic and toxicological aspects of carbon monoxide used in modified atmosphere packaging of meat. Trends in Food Sci. and Technol. 8: 307-312.

Table 1. Anaerobic growth rates of spoilage and pathogenic organisms in the presence of low and high CO2 levels (From Jones, 1989 and Lambert et al., 1991). *A: Aerobe, requires oxygen for growth; An: Anaerobe, inhibited by oxygen; F: Facultative, grows in the presence or absence of oxygen; M: Microaerophile, requires low levels of oxygen

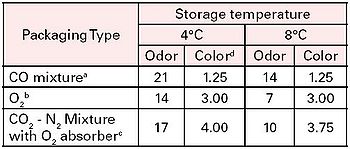

Table 2. Time for development of off odors (days) in pork loins stored at different temperatures and under different packaging conditions (Sorheim et al., 1999). a0.4%CO/ 60%CO2/40%N2; b70%O2/30%CO2; c60%CO2/40%N2 with O2 absorber in pack; dVisual color of the product on the day of off-odor development; 1=bright red, 5=extremely discolored

Fig. 1. Relationship of atmospheric oxygen concentration on myoglobin chemical state (Hunt, 2002)

Fig. 2. Relationship between myoglobin oxidation states and color of fresh meat (Fresh meat color triangle; Hunt, 2002).