Contents

- 1.1 Introduction

- 1.2 Toxic and Asphyxiating Gases

- 1.3 Dust and Particulate Matter

- 1.4 Potential Acute Hazardous Situations

- 1.5 How to Control Toxic and Asphyxiating Gases

- 1.6 Precautionary Measures

- 1.7 Other Safety Precautions

- 1.8 First Aid Procedures

Originally published as PIH-104.

Authors:

Kelley Donham, University of Iowa;

Robert Aherin, University of Illinois;

David Baker, University of Missouri;

Glen Hetzel, North Carolina State University

Reviewers:

James Barker, North Carolina State University;

Gerald Bodman, University of Nebraska;

Ken Kreig, University of Alaska;

John Sweeten, Texas A&M University

Introduction

Since the early 1970’s, the swine industry has continued to move toward specialization, mechanization, and enclosed housing for rearing of livestock. One aspect of this specialization is housing systems designed to raise animals with less labor in a more controlled environment that includes automatically controlled ventilation, liquid or slurry manure handling, and feed handling. These systems impose new environmental management requirements related to the health and productivity of both people and livestock. Proper environmental management is essential to ensure realization of the animal health and performance advantages of housing systems compared to pasture or open lot systems. Advantages of properly designed and managed systems include lower mortality, reduced morbidity, and better feed conversion efficiency with minimal degradation of the outdoor and working environments.

Manure that is stored or allowed to accumulate within enclosed buildings generates a variety of gases, some of which are toxic or asphyxiating. Unvented or improperly functioning LP or oil heaters in poorly ventilated buildings also can create problems, primarily due to elevated levels of moisture, carbon monoxide, and unburned hydrocarbons. Inhaled dust from dried manure, feed, and animal hair and dander can damage respiratory systems. The severity of these problems is often seasonal in that the atmosphere within enclosed buildings is usually better during warm weather. Reduced ventilation rates during cold weather allow concentrations of contaminants to increase.

The danger of gases from stored manure must be respected. Livestock and humans have died as a result of both ventilation system failures and high levels of toxic (hydrogen sulfide) or asphyxiating (carbon dioxide) gases. Human fatalities have occurred from entering a confined space where liquid manure is collected or stored without ensuring adequate ventilation or without being equipped with a supplemental air supply. Manure storages and lagoons also represent a drowning hazard.

Toxic and Asphyxiating Gases

Stored manure, urine, and wasted feed in water undergo anaerobic digestion. Over 150 different gases are produced as by-products, but major health concerns are caused by hydrogen sulfide, ammonia, carbon dioxide, and methane. Other groups of gases produced include volatile acids, amines, and mercaptans which are highly odorous in very small quantities. Methane, at the proper concentration, poses an explosion hazard.

In addition, carbon monoxide can rise to toxic levels when heating units are improperly maintained or malfunction and when inadequate oxygen is present. Hydrogen Sulfide (H2S). Hydrogen sulfide is the most acutely hazardous toxic gas associated with the anaerobic decomposition of swine manure. It is responsible for numerous episodes of deaths of livestock and humans associated with liquid manure storage pits. It is colorless and has the characteristic odor of rotten eggs. However, the odor of hydrogen sulfide can be deceiving. Most people can detect hydrogen sulfide at very low concentrations (below one part per million [ppm]). However, the gas has a deadening effect on the sense of smell, making detection extremely difficult even at high concentrations.

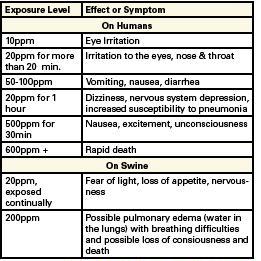

The background (ambient) level of hydrogen sulfide gas in a well-ventilated swine unit will be less then 2ppm. However, during agitation and pumping of liquid manure, hydrogen sulfide can reach dangerous concentrations. Levels of 200ppm to 1,500ppm have been measured within a few seconds after agitation begins. Exposures below 500ppm create severe tissue irritation and toxic effects on the nervous system. Above 500ppm, unconsciousness may result in just a few breaths. Death may follow. Unfortunately, many multiple death events have occurred as family members (or other would-be rescuers) attempt to save a victim. Even if a person does not lose consciousness after inhaling heavy doses of hydrogen sulfide, medical attention still should be sought because fluids can accumulate in the lungs. This can lead to a delayed reaction up to 24 hours after exposure. The specific effects of hydrogen sulfide on humans and swine, at different levels, are listed in Table 1.

The Occupational Safety and Health Administration (OSHA) publishes permissible exposure limits of toxic substances for workers. Exposure limits for hydrogen sulfide during an eight-hour work period are 10 ppm. Evacuation of workers is recommended when levels exceed 15ppm for more than 15 minutes (The OSHA short-term exposure limit is 15ppm). Reliable data on allowable long-term exposure are not available. Common sense suggests lower acceptable concentrations as exposure time increases. The maximum recommended concentration in the pig zone is 3ppm.

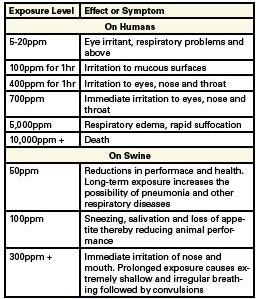

Ammonia (NH3). Significant amounts of ammonia are released from manure and urine from the storage pit, as well as from floor or slat surfaces. Ammonia gas is an irritant which is colorless and highly water soluble. It has a sharp pungent odor that becomes detectable at levels as low as 5ppm.

Typical ammonia levels in mechanically ventilated buildings are 5ppm to 20ppm with liquid manure systems and 10ppm to 50ppm where manure and urine are deposited on solid floors. Levels can exceed 50ppm with winter ventilation rates, and may reach 100ppm in poorly ventilated buildings.

Ammonia is primarily an irritant at levels found in swine buildings. Above 7ppm it will increase the risk for respiratory disease in workers, and above 11ppm it is related to increased pneumonia and lowered production parameters. At any level, it interacts with dust and endotoxin in the air to increase the tissuedamaging effect of the air. The specific effects of exposure to ammonia gas are presented in Table 2. The OSHA maximum ammonia concentration for workers during an eight-hour work period is 25ppm. The shortterm exposure limit for ammonia is 35ppm.

Carbon Dioxide (CO2). The earth’s atmosphere normally contains 300ppm of carbon dioxide. At considerably higher concentrations (>30,000 ppm), it can asphyxiate people by displacing oxygen available for breathing.

Manure decomposition, the normal breathing process of animals, and fossil fuel-burning heaters are the sources of carbon dioxide in confined spaces. Typical concentrations inside ventilated buildings range from 1,000ppm during well-ventilated periods to 10,000ppm during winter. Levels above 1,500ppm are associated with higher levels of respiratory disease and decreased productivity. The specific effects of excessive concentrations of carbon dioxide are presented in Table 3. The OSHA maximum carbon dioxide concentration for workers during an eighthour period is 5,000ppm.

Methane (CH4). Methane is produced during natural decomposition of manure and is non-toxic. It is rarely a problem in swine buildings. However, high concentrations can cause headaches and even asphyxiation. The major safety concern about methane is that it is highly flammable and can be explosive at levels ranging from 50,000 to 150,000ppm (5% to 15%). Because methane is lighter than air, it may rise and accumulate near the higher stagnant parts of enclosed buildings and tightly closed manure storage pits. This colorless, odorless gas is only slightly soluble in water. But if a unit is well ventilated, concentrations should be well below the minimum explosive point.

The OSHA maximum safe methane concentration for workers during an eight-hour period is 1,000ppm. The maximum recommended level in swine buildings is 500ppm. Its effects on humans and swine are primarily as an asphyxiant (Table 4).

Carbon monoxide (CO). Incomplete combustion of fossil fuels results in the production of carbon monoxide. This gas is most notorious for killing people who operate their car engines inside closed garages.

Inside a building, carbon monoxide can build up in poorly ventilated areas where heating units are poorly maintained or malfunction, where there are unvented heaters, where there are gas catalytic heaters, or where gas-powered high-pressure sprayers are used inside. Winter is the most dangerous period because buildings are usually closed and ventilation rates are lowest. A potential victim usually will be unaware of the presence of high levels of carbon monoxide because it is colorless and odorless. The OSHA maximum eight-hour exposure limit for carbon monoxide is 25ppm. Pregnant workers should be aware than an unborn fetus is more susceptible to carbon monoxide than adults. The same is true of small pigs. Carbon monoxide is slightly lighter than air and is insoluble in water. The effects of carbon monoxide exposure are presented in Table 5. The maximum recommended concentration in the pig zone is 15ppm.

Dust and Particulate Matter

Sources of high concentrations of dust particles inside swine units include feed, dried manure, and dander and hair from animals. Ammonia is absorbed into these dust particles, increasing their irritating effects. Particulate matter also includes viral, bacterial, and fungal agents. Although most of these organisms are not infectious, endotoxin and glucans (products of the decay of certain bacteria and fungi) can damage the respiratory tract.

Inhalation of animal feed dust containing antibiotics can increase a person’s allergic reaction to certain antibiotics. Some workers may contract infections that are resistant to antibiotics. Breathing dusty air for an extended time may yield one or more consequence. Some known consequences along with the percent of workers affected are listed below. They are based on current research from several different occupational health studies.

- Chronic bronchitis (signs: frequent cough bringing up phlegm) – (25%)

- Asthma (usually a non-allergic type; signs: wheezing and chest tightness) – (25%)

- Sinusitis (signs: continual cold, stuffy nose, headache, plugged ears) – (22%)

- Organic dust toxic syndrome—ODTS (signs: flu-like illness with fever, headache, fatigue, muscle aches and pain, occurs after especially heavy dust exposures) – (30%)

- Increased susceptibility to respiratory diseases such as colds and pneumonia – (percentage undetermined)

OSHA standards allow for exposure to 3mg/m3 respirable (dust particles small enough to be inhaled in the lungs) and 10mg/m3 total nuisance dust exposure. However, swine building dust is hazardous at much lower concentrations because of the toxic and irritant contents (e.g., endotoxin, glucans, ammonia, and swine dander). Research in the U.S. and Sweden has documented increased human health problems in buildings having greater than 2.5mg/m3. Furthermore, levels above 3.5mg/m3 are detrimental to animal health and production. Dust levels in marginally ventilated swine housing units during the winter are typically 3mg/m3 to 6mg/m3.

Potential Acute Hazardous Situations

Ventilation breakdown. A ventilation system malfunction can result in severe animal stress or death, particularly on hot, still days when no natural drafts occur to replace the air in animal areas. Animals may die from heat prostration, lack of oxygen, or a combination of these hazards – in just a few hours. The risk is greatest in buildings equipped with mechanical ventilation and inlets dependent upon fan operation to open. Systems which warn of ventilation system failure reduce the risk of death.

Manure agitation. Agitation of liquid manure that has been stored for more than a few weeks will release toxic levels of hydrogen sulfide. This situation can create lethal conditions, even when there is full ventilation. The greatest hazard exists almost immediately after vigorous agitation of stored manure begins. A manure storage should never be agitated except with full operation of the ventilation system. With non-mechanically ventilated buildings, select a breezy day and open all ventilation openings.

Entering a manure storage. A manure storage pit should never be entered without a self-contained air supply, a properly affixed harness and lifeline, and at least two persons with sufficient equipment to pull the person out if the need arises. Even if a pit has been ventilated or recently emptied, a person could be killed by residual hydrogen sulfide gas or by the lack of oxygen.

Open manure storages, tanks, or lagoons. Any unguarded opening into a deep manure storage or tank presents a hazard. Workers and animals could fall into the pit and drown. Surface scums and crusts can be deceiving. Although they may appear capable of supporting a person’s weight, most will not do so.

Heaters and engines. Unless there is adequate ventilation where space heaters, catalytic heaters, and radiant heaters are used, carbon monoxide can reach hazardous concentrations. Another hazard is the use of internal combustion engine-powered auxiliary electric generators or gas-powered high pressure sprayers that are not vented to the outside. To assure safety, these engines should never be run inside.

How to Control Toxic and Asphyxiating Gases

Environmental assessment. Livestock buildings should be measured for dusts and gases at least twice yearly. Measurements should be taken in the fall as ventilation rates are decreasing, and again in December or January. Environmental assesment services are available from consulting veterinarians and engineers, extension personnel, and the agricultural health and safety programs conducted by some states. Collected data should be used to develop a control plan aimed at removing the source of the contaminant. Source control for dust may include adding fat or oil to feed, frequent power-washing of the building, eliminating manure buildup, adding drop tubes to feed augers, installing covers on feeders, and modifying the diet or parasite control program to help assure healthy skin.

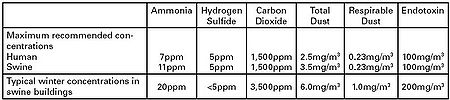

Data are now available for recommended maximum exposure for swine buildings. These levels are lower than OSHA limits because of the toxic nature of swine dust, the combined effects of the various gases, and the 24-hour exposure of the pigs. Table 6 shows the maximum recommended concentrations for human health (both OSHA legal limits and recommendations based on current research) and swine health and productivity, as well as the average winter levels. Buildings should be evaluated and managed to meet these levels to help assure health and productivity of the people working in the buildings and the livestock.

Assure adequate ventilation. Ventilation systems should be designed to ensure adequate air exchange rates within animal and worker zones. When conserving heat during the winter, be sure to maintain ventilation rates at or above the minimum recommended. Consider using air circulation fans or distribution ducts to improve the mix of indoor air during the winter. In addition to maintaining adequate ventilation, observe

these management tips:

- Maintain the ventilation systems by frequently removing dust accumulations from exhaust fans, fan shutters, and air inlet screens and controls.

- Make sure manure pump-out ports are covered to assure air is not “short circuited” around the proper inlets.

- Provide the maximum amount of mechanical ventilation possible whenever stored manure is agitated. In a naturally ventilated building, agitate only when there is a brisk breeze; and even then, consider removing livestock from the building before agitating the manure.

- Stay outside the building while agitating and pumping manure. If animals show signs of distress, discontinue agitation. Do not enter the building for at least 30 minutes.

- Install an alarm system to warn of power failures that would affect the mechanical ventilation system. Check and maintain the alarm system and power unit on a weekly basis. If power fails, an emergency power generating unit should start immediately. If an auxiliary unit is not available, open all windows and doors and consider removing livestock from the building.

- Use proper manure storage management. Do not overfill underfloor manure storage pits. The storage should be pumped or drained when the liquid level rises to within 1 foot of the slats or to within 4 inches of the bottom of slat support beams. After emptying a storage, add enough liquid to cover the remaining residue and manure solids. Hydrated lime (construction lime) can be added to manure storage contents at the rate of 1 pound per 1,000 cubic feet of stored manure to maintain the pH near 7. Alkaline conditions suppress the release of hydrogen sulfide but increase ammonia emissions.

- Place gas traps in drain lines connecting outside manure storage structures with enclosed buildings to prevent reverse flow of gases into the building.

- Assure continuous ventilation if any type of unvented heater is to be installed. Vent all engine exhausts to the outside to minimize carbon monoxide levels.

Precautionary Measures

- If possible, evacuate all animals and workers from buildings before stored manure is agitated. If animal evacuation is not possible, observe from a distance, start agitation slowly and be ready to turn off the pump at the first sign of distress. See Tables 1-5 for effects of exposure to gases. Do not agitate vigorously at the start. Instead, begin agitating at close to tractor idle speed and slowly build up the pump speed, while observing the animals. Shut down the agitator at first sign of animal distress, but do not enter the building without allowing time for complete ventilation or using a self-contained breathing apparatus.

- Never enter a manure storage when agitating. Never try to rescue a distressed animal or person without being equipped with a self-contained breathing apparatus that has its own oxygen supply.

- Enter a manure storage pit or tank only when it is absolutely necessary. Even then, only do so if it is well-ventilated, you are wearing a self-contained breathing apparatus with a harness and lifeline attached, there are at least two persons available to pull you out in the event of a problem, and appropriate rescue equipment is available. Make certain a similarly equipped person who is capable of retrieval is ready and strategically located for rescue.

- Be aware of the signs which indicate gas has reached toxic levels. For long term, these signs include rapid blackening of copper pipes, electrical wiring, or leadpigmented paint–or white deposits of zinc sulfate on galvanized steel. Approved commercial gas monitors, measuring devices, or kits can be used to check current gas levels.

- To help prevent the risk of drowning, install covers or grates on all ground-level and below-ground manure collection and storage tanks. Once installed, keep these access covers in place. Covers should be designed and installed in a manner which prevents them from falling into the pit. Install railings around all manure storage pit or tank openings, and along all walkways, piers, or catwalks beside or over the open storage areas. Attach permanent ladders made of non-corrosive material to the inside wall of all deep manure storage structures.

Other Safety Precautions

- Fence-in earthen manure storage basins and lagoons to prevent accidental entry by animals and people. Remind people, by posting warning signs, to stay out and exercise utmost caution.

- Prohibit smoking, welding, or the use of open flames in poorly ventilated buildings or enclosed manure storage areas.

- Use explosion-proof electric motors. Keep light fixtures and electric wiring around storage structures in good condition. All electrical wiring should meet the National Electric Code.

- Place flame arrestors on the gas lines that lead to heating units or generator engines. If there is an anaerobic digester system for methane production, there should be signs “Caution-Flammable” posted in plain view.

- Keep all guards and safety shields in place on equipment such as pumps, manure spreaders, and power units.

- Stand clear of “tipping bucket” flush tanks when they rotate.

- When working in enclosed buildings for a prolonged period (more than 2 hours per day), reduce inhalation of dusty air by wearing a disposable dust respirator which has been approved by the National Institute for Occupational Safety and Health (NIOSH). Look for the NIOSH approval label on the respirator you intend to wear.

First Aid Procedures

- Be able to recognize symptoms of gas poisoning and the physical effects that occur as a result of exposure to products resulting from manure decomposition and/or faulty heating units.

- Locate rescue equipment and first-aid supplies that meet the approved standards of a consulting physician near the manure storage area.

- Post the phone number of the local fire department or rescue squad and a qualified physician near rescue equipment and beside all telephones.

- Do not attempt to rescue a victim from a storage pit unless you are equipped with a self-contained breathing apparatus, have a proper rescue harness in place, and have assistance to get you out.

- React quickly to any developing emergency to prevent the situation from becoming critical. During the phone call for assistance, make sure rescuers know what the situation involves so they can determine the need for special equipment.

- Get the victim to fresh air if movement can be done safely.

- Flush irritated areas of the body with fresh water.

- Start cardiopulmonary resuscitation (CPR) immediately, if properly trained, if the victim is not breathing and continue until medical help arrives.

Table 1. Effects of hydrogen sulfide exposure on humans and swine

Table 2. Effects of ammonia gas exposure on humans and swine.

Table 3. Effects of excessive carbon dioxide exposure on humans and swine.

Table 4. Effects of methane exposure or presence on humans and swine.

Table 5. Effects of carbon monoxide exposure on humans and swine.

Table 6. Recommended maximum concentration of toxic dust and gases in swine confinement buildings.