Contents

- 1.1 Introduction

- 1.2 The Adaptability of the Pig

- 1.3 What Constitutes the Pig’s Thermal Environment?

- 1.4 What Is an Optimum Thermal Environment for Pigs?

- 1.5 Measurements to Assess the Thermal Environment

- 1.6 The Effective Environment of the Pig

- 1.7 Defining Cold and Heat Stress

- 1.8 Recognizing and Controlling Cold Stress

- 1.9 Recognizing and Controlling Heat Stress

- 1.10 The Economics of Optimal Thermal Environments

- 1.11 Environmental Control Methods

- 1.12 Summary

Originally published as PIH-54.

Author:

Steven J. Hoff, Iowa State University

Reviewers:

George Grandle, University of Tennessee;

Robert Bottcher, North Carolina State University;

Jay Harmon, Iowa State University

Introduction

Economies of scale and the greater need for efficiency have resulted in the vast majority of pigs being raised indoors. These artificial environments have a great impact on production performance and the health status of both the pig and the worker. With the pork industry becoming more integrated, uniformstyle barns are built in multiples, and an error in design can be multiplied many times over. This situation highlights the continued need for adhering to basic design principles in ventilation and environmental control.

The environment surrounding the pig is a complicated influence that is often difficult to assess. For example, studies have shown that pigs can be subjected to very high levels of ammonia for a relatively long time with little adverse production effect. However, adding dust, other gases, and humidity with high ammonia is a potentially disastrous combination. The synergistic effects of gases and dust are complicated and potentially very serious for the health status of not only the pig but of the workers as well. This report summarizes the requirements of the thermal environment, assessing the thermal environment, the economics of maintaining optimal thermal environments, and best management practices to achieve these environments.

The Adaptability of the Pig

The pig is very adaptive to its environment, which is one of the complicating factors that often prevents a producer from recognizing potential problems. However, in many cases, adaptive responses to the environment take feed energy away from growth and use it to fuel the adaptive response. For example, shivering is a response to combat cold stress by generating internal heat via muscle friction. This reaction often goes unnoticed; and while it is occurring, the pig is wasting feed energy to frictional losses that would otherwise go to growth.

This adaptive response, multiplied by hundreds of pigs under one roof, can make a substantial difference in profitability.

What Constitutes the Pig’s Thermal Environment?

The thermal environment for the pig involves all factors that affect energy exchange between the pig and its surroundings. Energy exchange, in the form of heat, is transferred between the pig and its surroundings by four basic methods of heat transfer: conduction, convection, radiation, and evaporation. Conduction, convection, and radiation are grouped into sensible heat, which implies that a temperature difference is required to exchange heat by these methods. This temperature difference is between the pig’s core, or surface, and the surrounding surfaces (conduction and radiation), or the surrounding air (convection). Evaporation is a method of transferring large amounts of heat by the exchange of moisture between the surrounding air and the pig’s respiratory tract (i.e., breathing) or the pig’s surface during sprinkling events. Understanding how pigs lose or gain heat energy is a key to understanding the interaction between the pig and its environment. More detail on these methods is described below.

Conduction. This method of transferring heat occurs as a result of the pig being in physical contact with another surface with a temperature that differs from the core temperature of the pig. A pig, with a core temperature of about 103°F, lying on a concrete floor with a temperature of 70°F loses heat to the floor with an overall temperature difference of 33°F. Heat is conducted from the pig to the floor by traveling through the pig’s tissue and then to the concrete. The major components that affect the rate of conducted energy are the core-to-floor temperature difference, the conductivity of the floor and pig tissue, and the contact area between the floor and the pig. A standing pig loses very little heat to the floor via conduction compared to a laying pig because the contact surface area is very small in comparison. Pigs may actually use this to their advantage by adjusting the amount of contact they have with the floor, by sprawling to make a lot of contact when they are too hot.

Convection. This method of transferring heat occurs as a result of the pig being in physical contact with air or mud or water at a temperature that is different than the core temperature of the pig. Technically, the temperature difference for this method of heat transfer occurs between the pig’s surface temperature and the surrounding fluid. But ultimately the pig’s surface temperature is dictated by the pig’s core temperature and the resistance to conduction heat transfer of the pig’s tissue components. The major components that affect the rate of convection energy are the surface-to-fluid temperature difference, the speed of the fluid, and the contact area between the pig and the fluid. This method is employed when fans are used to blow air on the pigs to reduce heat stress. Cold drafts are a negative example of convection.

Radiation. This method of transferring heat is by far the most complicated method to describe accurately. Radiation heat transfer occurs as a result of the pig “radiatively seeing” surfaces at a temperature that differs from the pig’s surface temperature. For example, if a pig is standing in a pen, in a curtain-sided barn, and if the curtain is at a temperature lower than the pig’s surface temperature, the pig will lose heat radiatively to this curtain. This same principle applies to all surfaces that the pig radiatively sees. The major components that affect the rate of radiation heat transfer are the pig’s surface exposure to all other surfaces in the barn, the thermal reflective properties of the pig and all other surfaces, and the amount of area from the pig that radiatively sees every other surface in the barn. Radiation heat transfer can easily account for 50% or more of the total heat lost (or gained) by the pig. An example of this is a person standing in front of a large window during the winter. Even though the air is warm, they lose heat, and therefore feel cold because of being exposed to the cold window surface.

Evaporation. This method of transferring heat occurs as a result of water conversion to a vapor. The amount of energy required to accomplish this conversion is called the latent heat of vaporization. For water, approximately 1000 Btu of energy are required to evaporate one pound of water. Therefore, for every pound of liquid water that is evaporated from the pig’s respiratory tract, 1000 Btu of energy from the pig are exhaled with the vapor and added to the surrounding room. Likewise, properly controlled sprinkler systems can be used to provide an artificial sweating mechanism for pigs. The major components affecting the rate of evaporation heat transfer are the water vapor content (or relative humidity) and temperature of the surrounding air, the speed of air moving over the wetted portion of the pig, the wetted surface area, and the volume of air respired by the pig in time. As the air and surface temperatures surrounding the pig get closer to the pig’s core temperature, evaporation heat transfer becomes the only method that pigs can use to lose heat and therefore sustain life.

What Is an Optimum Thermal Environment for Pigs?

An optimum thermal environment for a pig is an environment that does not require an extraordinary response by the pig to maintain a constant core temperature. This is a complicated way of saying that the pig, being warm blooded, is always in a mode of sustaining life. Life is sustained in one major way by keeping core temperature constant. If the thermal environment is cold, the pig responds by huddling, shivering, redirecting blood flow to the core, or excessively eating because too much thermal energy is lost to the environment. To make up this difference, more energy is needed, or needs to be conserved. Likewise, a thermal environment that is hot invokes heat loss increasing mechanisms such as panting, lying spread out on cool floors, wallowing in mud, and suppressed eating, to name a few. These responses to cold and hot are all extraordinary measures required by the pig to maintain a constant core temperature. All imply that an optimum thermal environment does not exist.

The previous examples referred to cold and hot. Temperature is only one thermal factor contributing to a cold or hot thermal environment. For example, an air temperature of 60°F is considered very good for 150lb. pigs. However, this air temperature, combined with a 100 feet per minute air flow would actually be considered cold since the pig’s convection heat loss to the environment is high, requiring energy conservation measures to maintain a constant core temperature. One must be very careful when assessing the pig’s thermal environment. All factors that affect energy exchange with the thermal environment must be assessed to arrive at the proper conclusion.

Measurements to Assess the Thermal Environment

The most important, most obvious, and easiest measured environmental factor is air temperature. Air temperature, relative to pig temperature, determines the level of energy exchange between the pig and its surroundings by convection and evaporation and indirectly through radiation. Air temperature is most easily measured with standard mercury bulb thermometers or digital-based sensors.

Second, the speed of air moving over pigs is another important factor. Air flow directly affects both convection and evaporation methods of heat transfer. Air flow can be measured with either digital-based sensors or simple vane or paddlewheel sensors.

Third, the surrounding surface temperatures are critical indicators of a pig’s thermal environment. Surface temperatures in contact with the pig affect conduction heat transfer and surface temperatures surrounding the pig affect radiation heat transfer. Surface temperature measurements can be made by an infrared thermometer and are a little more difficult and expensive to make, but nevertheless a critically important indicator.

Fourth, the water vapor content of the surrounding air, combined with air temperature, directly affects the evaporation of liquid water. A device called a psychrometer can be used to determine the actual water vapor content of the air. A measurement of relative humidity is, as the name implies, a purely relative measurement and does not directly define the actual water vapor content of the air.

The Effective Environment of the Pig

The term Effective Environmental Temperature (EET) has been used for many years by researchers and academicians and has recently found its way into the pig industry. The EET refers to the combined influences of many environmental factors that define the level of energy exchange between the pig and its surroundings. For example, a pig exposed to 70°F temperature with low air flow is being subjected to a very different thermal environment than a pig exposed to 70°F temperature with high air flow. The effective environment for the pig in high air speed is much cooler because the pig is losing more heat to its surroundings via convection. This is similiar to the term “wind chill” used in giving winter weather reports. Likewise, if we compare two barns, maintained at the same air temperature, both with low air flow, with one of the barns having little or no wall insulation, each will “thermally” affect the pig in a very different way. With little wall insulation, pigs will radiatively “see” cold walls during the winter and thus their effective environment will be cooler, represented by a lower EET.

The EET is convenient (put into “temperature” terms) and easily understood. The specific methods used to calculate EET are complicated and beyond this discussion, but the concept is important. The most important thing to remember is that the comfort and performance level of the pig is directly influenced by how readily (or unreadily) the thermal environment takes (or gives) energy in the form of heat to (or from) the pig. If the air temperature is below the core temperature of the pig, then a hot, still environment has a higher EET than a hot, high air speed environment. However, if the air temperature is above the core temperature of the pig, then the barn with the lower air speed will have a lower EET. Why? Because if the air temperature is above the core temperature of the pig, then a higher air speed will force heat into the pig at a faster rate than a still air environment by the method of convection. Many pigs have been lost through heat stress by increasing air speed when the air temperature reaches or exceeds the core temperature of the pig because it effectively makes the environment hotter.

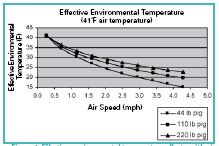

Figure 1 is an example EET that relates pig size and environment (air speed) at an actual air temperature of 41°F.

As might be expected, younger pigs are more susceptible to higher air speeds than mature pigs. Intuitively this makes sense, but how can this be explained from an energy exchange point of view? Remember, the thermal comfort of a pig is a direct result of energy exchange with its environment, so this result should be able to be explained from a heat transfer point of view. Air temperature and air flow directly affect convection heat transfer. Also, the pig’s surface area exposure to an environment directly affects convection heat transfer. For young pigs, the surface area to weight ratio is higher compared to mature pigs. Therefore, for any given combination of air temperature and air flow, a young pig, per pound of body weight, will transfer more heat to or from its surroundings implying that the effect of air flow is greater for younger pigs.

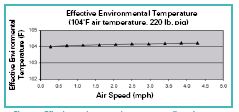

The EET chart given, developed for the combined influences of air temperature and flow, also highlights two other important facts regarding a pig’s energy exchange. First, as indicated with this chart, the influence of air flow on the pig’s thermal environment decreases with increasing air speed. This occurs because of a boundary layer of air that exists on the pig’s surface. This boundary layer of air acts like a blanket of insulation. This boundary layer decreases with increasing air speed, but can only be decreased to a given minimum. Therefore, at some air speed level and beyond, the convection heat transfer to the surrounding air reaches a maximum. This maximum occurs at about 3.5 miles per hour, and this is the reason why tunnel ventilated barns are designed for a maximum air speed of about 3.5 miles per hour. Beyond this level, we have reached a point of diminishing returns via convection. Second, as air temperature increases, the influence of higher air speeds decreases. In fact, if the air temperature is exactly equal to the pig’s surface temperature, no heat can be transferred by convection methods, regardless of air flow. Without a difference in air temperature, no heat can be transferred via convection. This example is shown in Figure 2, where pigs are exposed to a 95°F air temperature.

The pig’s response to its thermal environment and the resulting EET play a big role in how best to control an optimum thermal environment. For example, young pigs, because of their susceptibility to high air flow, need ventilation systems and environmental control strategies that reduce any potential drafting air flows. With more mature pigs, less attention is needed to this detail. Also, it is important that a control system recognizes when it might be dangerous to artificially increase air flow during extremely hot conditions. As Figure 3 shows, high air speed combined with extreme air temperature actually hastens heat stress, unless some form of evaporative cooling is present.

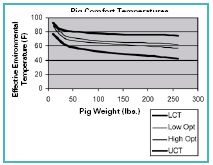

Defining Cold and Heat Stress

The lower critical temperature (LCT) is generally accepted as the effective temperature of the thermal environment where pigs will need to consume more feed and apply extraordinary measures to keep warm. Likewise, a pig’s upper critical temperature (UCT) is generally accepted as the effective temperature of the thermal environment where pigs suppress feed intake and apply extraordinary measures to keep cool. Between the LCT and UCT, there is an optimum thermal environment region, depending on pig age, where pigs will perform best. Our goal in any environmental control method is to achieve this region of effective environmental temperature that optimizes production efficiency. The LCT and UCT are both functions of pig age as Figure 4 indicates.

The optimum temperature range is the band of EET that a control system should be designed to achieve. EET levels outside this band of temperatures diminish production efficiency.

Recognizing and Controlling Cold Stress

Behavioral responses by the pig can be an indicator of cold stress. Pigs huddling is a sure indication that they are feeling cold as a result of air temperature, air flow, flooring temperature, surrounding wall temperature, or a combination of any of these factors. A simple strategy for controlling cold stress is simply to raise the air temperature in the barn. However, this can be an expensive option. A better approach would be to assess the environment to determine the cause of cold stress. An assessment of air flow may indicate elevated levels, and an adjustment of the inlet air direction may be all that is needed to control cold stress.

Recognizing and Controlling Heat Stress

Like cold stress, behavioral responses by the pig can be a good indicator of heat stress. For example, heavy breathing or panting is a clear indication that pigs are attempting to lose more heat to their surroundings via evaporation methods, and this is a clear behavioral response to heat stress. Pigs suppress eating and increase water intake during periods of heat stress. Also, lying patterns become very spread as pigs attempt to increase their surface area to the surroundings. All these responses are clear indicators that the pig is heat stressed. Controlling heat stress can be accomplished with two major methods: direct and indirect cooling. Direct cooling is any method that directly contributes to the increase in heat transferred to the surrounding area. An obvious example of this would be to sprinkle the pig’s body with water and allow energy from the pig to supply the needed latent heat of vaporization to evaporate this water. This direct cooling method can be further increased by increasing the air speed over the wetted surface of the pig. In contrast to this, indirect cooling would involve cooling the air surrounding the pig and relying on convection to increase the heat transferred to the surrounding area. As a general rule, direct cooling is much more efficient in removing excess heat from the pig, and should be the first line of defense against heat stress.

In extreme heat stress conditions, increasing the air speed over the pig without the addition of liquid water for evaporation can actually be detrimental. Figure 3 outlined this case for 220lb. pigs. If the air temperature is 104°F, which is slightly above the 103.5°F core temperature of the pig increasing the air speed actually increases the EET since now the effect of increased air speed is to convectively add heat to the pig at increasing rates.

The Economics of Optimal Thermal Environments

No one should implement sophisticated environmental controls or housing systems unless evidence exists that there is a benefit. A benefit might be decreased labor expense, a decrease in disease outbreaks, an increase in profitability, an increase in worker job satisfaction, or any number of reasons that the producer feels is a benefit to the operation. Evidence does exist that there is a clear economic benefit for maintaining an optimal thermal environment for the pig.

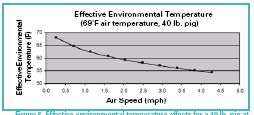

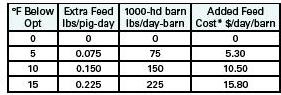

For example, studies have shown that for every degree Fahrenheit below the optimum temperature, pigs less than about 60lb. need to consume 0.015lb./day more feed and pigs greater than about 80lb. need to consume 0.044lb./day more feed to supply the extra energy that is being lost to the pig’s surroundings. Table 1 gives a more complete picture of this trend for a 1000 head facility housing 40lb. pigs. For the example case given in Table 1 for 40 lb. pigs, the criteria for achieving the degrees of coldness listed can be met in several ways. In a well-insulated barn with low air speeds at pig level, maintaining the barn at 5°F, 10°F, or 15°F below the optimum temperature of 69°F will achieve the degrees of coldness listed. Likewise, using the concept of effective environmental temperature, this same degree of coldness could be achieved in a well-insulated barn, maintained at 69°F, with pig-level air speeds of 0.8 mph, 2.0 mph, and 4.5 mph, respectively (see Figure 5). The condition of 15°F coldness seems to be very severe, and one would think never attainable in a barn unless a ventilation control problem exists, thus forcing the actual air temperature to this level. However, when viewing this issue from an effective environmental temperature viewpoint, a well-insulated barn with a drafty environment can easily attain these levels of coldness.

Environmental Control Methods

Many different designs exist today to modify the pig’s thermal environment. A wide variety of control systems, ventilation arrangements, and building designs exist from which to choose the best system for a given situation. There are no hard and fast rules for making these decisions, but a few guiding principles should be kept in mind.

The climate. Building design is most often the result of climate and pig maturity level. For example, a naturally ventilated (NV) barn for finishing pigs in North Carolina would be doomed to failure because in the heat of the summer, as much as 14% of the time the wind is calm. Since the primary hot weather ventilation force for NV barns is wind, at least 14\% of the time the barn would be grossly under-ventilated causing severe heat stress conditions. Likewise, a tunnel ventilated (TV) barn for finishing pigs in Iowa is needed very few times during the year because during the heat of the summer, it is calm less than 2 percent of the time. Much of the summer can be very nicely ventilated with pure NV methods. The environmental control system should be intelligent enough to make a decision between transition from/to NV or TV.

The desire. What is your objective as a producer? If your objective is to create a tightly controlled environment prepared for any climate, then a sophisticated ventilation design and control system is required. If you are trying to simply keep animals from the severest climates, then a partially enclosed building with no active ventilation or control system is adequate.

The classification on control usually falls under one of the following groups: cold, modified, or controlled environments. No attempt is made with cold facilities to control the ventilation process with most of the building open to the outdoors. For these facilities, typical of modified open-front buildings, almost no attempt is made to reach optimum growing conditions. A modified building usually has some insulation, manually controlled curtains and/or ridge vents, and a heating system to keep any water lines from freezing. The objective with this design is to maintain the inside temperature slightly above outside with swings in temperature following the outdoor temperature. In a controlled building, a great deal of attention is given to controlling the environment to remove unwanted variations. With these designs, usually the latest and most sophisticated ventilation and control strategies are incorporated, with various ventilation strategies in one building to respond to varying climates by season.

Summary

Depending on your desire as a producer, several options exist for maintaining a thermal environment at levels you desire. Pigs surely will adapt to the environment, but many times it is at a cost. This cost might be in the form of extra feed intake during periods of cold stress, or suppressed feed intake and growth during periods of heat stress. Evaluating the environment at regular intervals and assuring maintenance of the environment within an optimum range of effective environmental temperatures will efficiently house pigs and most likely reduce the susceptibility from thermally induced stressors.

A wide variety of technologies exist to help assess the thermal environment. Hand-held instruments and periodic observations of pig behavior can be used to evaluate the thermal environment and provide the producer with feedback for making any required changes to the environment. Sophisticated control systems exist to provide continuous monitoring of the thermal environment and necessary control modifications to the barn in an attempt to achieve the optimum thermal conditions for pork production. This level of sophistication now allows for barns to be controlled not only for air temperature, but also for humidity and air flow levels in an attempt to assess and control the effective environment of the pig. In today’s pig production industry, a mistake in thermal environmental control can be costly, as small, added costs of production are multiplied through many similar barns and pigs.

Table 1. The effect of air temperature on feed intake of 40lb. pigs. *$0.06/lb feed cost

Figure 1. Effective environmental temperature effects with air speed at 41˚F actual temperature

Figure 2. Effective environmental temperature effects with air speed at 95˚F actual temperature.

Figure 3. Effective environmental temperature effects for a mature pig at 104˚F actual air temperature.

Figure 4. Pig comfort temperature.

Figure 5. Effective environmental temperature effects for a 40 lb. pig at 69˚F actual temperature.