Contents

- 1.1 Postmortem Changes in Muscle Tissue

- 1.2 Effects of abnormal post-mortem metabolism on meat quality

- 1.3 Preventing PSE

- 1.4 Impact of chilling on palatability traits

- 1.5 Practical Considerations

- 1.6 Chilling Mechanisms

- 1.7 Chilling Methods

- 1.8 pH and Temperature Decline

- 1.9 Carcass shrink

- 1.10 Color and Tenderness

- 1.11 Drip Loss

- 1.12 Summary

- 1.13 References

Originally published as a National Pork Board/ American Meat Science Association Fact Sheet.

Authors:

Elisabeth Huff-Lonergan, Jennie Page Iowa State University

Reviewer:

Roger Johnson, Farmland Foods

Postmortem Changes in Muscle Tissue

Muscle is a highly complex tissue that works within a narrow range of physiological conditions. After an animal is harvested, conditions within the muscle change, and muscle gradually loses its ability to function. As a consequence, a number of physical and chemical changes take place over time as muscle is converted to meat. It is the rate and the extent of these changes that influence the ultimate quality attributes of the resulting meat products.

After an animal is slaughtered, a vast series of postmortem changes begin to take place. Following exsanguination, the circulatory system can no longer transport nutrients and oxygen to the muscles or remove waste products and heat. Therefore, once the circulatory system ceases to function, oxygen in the muscle becomes depleted. When oxygen in muscle is depleted, glycogen metabolism (used to produce energy in the form of ATP) shifts from aerobic pathways, which use oxygen, to anaerobic pathways, which do not require oxygen. A by-product of anaerobic metabolism is lactate. In living muscle, any lactate that is produced is eventually removed from muscle via the circulatory system. After slaughter, the circulatory system can no longer remove lactate from themuscle; therefore, the lactate gradually builds up in the muscle and causes the pH of the tissue to decline. Lactate continues to accumulate in tissue until glycogen stores in the muscle are depleted, or until the pH is too low for the glycolytic enzymes to function. As lactate accumulates, the pH of the tissue drops from 7.4 in living tissue to approximately 5.6 in meat within about 24 hours. Muscles that have high levels of glycogen can ultimately produce meat that has an abnormally low pH. In addition, muscles from animals that have a hig hrate of metabolism immediately prior to slaughter will have a faster rate of glycogen utilization and pH decline after slaughter than muscles from animals with a slower or normal rate of metabolism. Therefore, both the rate and the extent of pH decline have major impacts on meat quality.

Effects of abnormal post-mortem metabolism on meat quality

When the rate of pH decline is gradual (from approximately 7.4 to 5.6 over a period of 6-12 hours), there will be a modest decrease in water holding capacity and an increase in shelf life due to the lowered pH of the product. However, severe, rapid decline of pH in muscle at an early time postmortem (while the carcass is still near living body temperature) causes extensive denaturation of many proteins including the pigment in meat, myoglobin. The resulting product is lighter in color because severely denatured proteins tend to reflect rather than absorb light. In addition,since these denatured proteins also have a much reduced capacity to bind water, there can be ultimately a severe loss of water-holding capacity. Product formed in this situation is termed PSE or pale, soft and exudative.

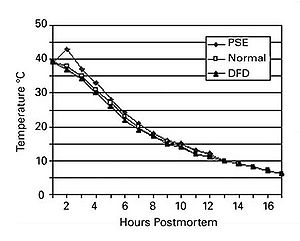

Also, as a consequence of exsanguination, the tissue loses its ability to regulate temperature. After exanguination, the circulatory system is no longer available to help remove heat from the deeper muscles of the carcass. Therefore, the temperature of these muscles can rise shortly after slaughter. This is especially true in animals that are stressed prior to slaughter or are genetically predisposed to producing PSE meat. The higher metabolic rates found in these pigs not only increases the rate of pH decline, but also increases the initial heat production of muscle tissue. As temperature increases, the rate of metabolism increases, in turn causing an accelerated pH decline. PSE product is prone to occur if the pH of the muscle falls to 5.8 or lower while the muscle temperature is above 95°F (35°C). This combination of high muscle temperature and low pH can greatly affect meat quality by causing severe denaturation of myoglobin and other proteins. In carcasses that are prone to producing PSE meat, the temperature can increase slightly after death before it drops (Figure 1). The overall rate of temperature decline in these carcasses is slower than the temperature decline for normal carcasses.

Preventing PSE

Chilling meat as soon as possible after exsanguination is one way to effectively alter the rate of temperature and pH decline. By rapidly chilling the carcass, the opportunity to have the situation of high temperature and low pH (more acidic conditions) is minimized. Lowering the temperature of the meat slows metabolic processes and reduces the rate of pH decline. By slowing the rate of pH decline, the severity of the denaturation of myoglobin and other proteins is reduced and the color and water-holding capacity of the meat may be improved. Therefore, intensive and early chilling may prevent mild cases of PSE by avoiding the combination of both high temperature and low pH. In severe cases of PSE (usually caused by the presence of the Halothane gene), the rapid pH drop makes it difficult to lower the muscle temperature fast enough to prevent protein denaturation.

Impact of chilling on palatability traits

Besides affecting water holding capacity and color, chilling can also affect tenderness. When the temperature of the tissue is dropped to an extremely low temperature prior to reaching its ultimate pH, less tender product can result (Jeremiah et al., 1992, Jones et al., 1987). A very low muscle temperature at an early time postmortem destabilizes the ability of the major calcium storage site in the muscle, the sarcoplasmic reticulum, to sequester calcium.This can cause calcium to be released and signal the muscle to contract (if there is sufficient energy), thus shortening the muscle. This shortened muscle is more dense and lesstender. In extreme chilling conditions, the temperature of small diameter muscles near the exterior of the carcass may fall faster than in larger diameter muscles, possibly rendering them more susceptible to chilling- induced toughening.

Practical Considerations

The relationships between pH and the rate of temperature decline of the carcass have very real implications for pork quality. Pale, Soft, and Exudative (PSE) pork develops if the pH drops very rapidly while the muscle is still very warm. A very rapid chill could then have the potential to reduce the frequency of some PSE pork. However, if the temperature drops too rapidly while the pH is still above 6.0, cold shortening might occur. In muscle with normal postmortem metabolism, if the temperature is dropped too rapidly, the ATP concentrations (needed to provide energy for the contraction cycle) may still be high. In this scenario, once muscle drops below 59°F (15°C) calcium is released from the sarcoplasmic reticulum. This calcium, in concert with the remaining ATP, can trigger severe muscle contraction and shortening. Once the ATP is depleted, this contraction is irreversible, causing the meat to be tougher and lose moisture. Moisture may be lost due to constriction of the cell resulting in less space for water to reside in shortened muscle. Cold shortening, as this is termed, is rare in pork carcasses and is more likely to occur with product that is hotboned. To prevent cold shortening, it is recommended to not chill pork carcasses below 41°F (5°C) while the muscle pH is greaterthan 6.0. When hot boning, it is recommended to not drop the temperature of the meat below 59°F (15°C) while the muscle pH is greater than 6.2 (Honikel, 1999).

In PSE prone muscles, if the temperature is 102–104°F (39-40°C) at one-hour postmortem, PSE can develop. Cold shortening will be prevented by a chilling regime that maintains the muscle temperature above 59°F (15°C) for as long as a significant amount of ATP is present. In normal muscle, significant ATP will be present for the first 3-4 hours postmortem. In the loin, an optimum loin-chilling rate (Figure 2) can be achieved by considering all of these factors. In normal ham muscles, the temperature needs to be at least 95°F (35°C) or lower within 2.5 hours after slaughter and should reach at least 44°F (7°C) or lower by 22 hours after slaughter.

Chilling Mechanisms

The purpose of chilling is to remove heat from the carcass as quickly as possible after slaughter. This is accomplished by transferring heat from the carcass to the atmosphere or to another material. This transfer is done by convection or by conduction. In order to be effective in meat products, heat transfer needs to be done quickly. This is important because the temperature of the carcass, the time it takes for the carcass to chill and the rate of pH decline must all be taken into consideration. All of these factors affect pork quality. Furthermore, an increase in shelf life and safety of meat can be accomplished by chilling. Chilling creates an environment that is unfavorable for microbial growth. Therefore, the rapid removal of heat from pork carcasses is an essential step in meat production.

There are two major mechanisms for removing heat from carcasses; convection and conduction. Convection is a mechanism of heat transfer that is due to flow. Heat is transferred from the surface of the product into a cooling medium that passes over the product. Water and air are the most commonly encountered media. There are two types of convection; free or natural convection and forced convection. Free convection is flow due to fluid density differences because of a temperature gradient. An example of a situation in which free convection is the primary mode of cooling would be when a carcass is hung in a still airfreezer or cooler (no fans on). In this situation, the carcass will slowly move from a hot state to a cold state due to the temperature difference between the carcass (product) and the still air (cooling medium). Forced convection utilizes mechanical methods to induce flow. Cooling a product by blowing chilled air across the surface is an example of mechanical means to induce cooling by forced convection.

The rate of heat removal from the product depends on the surface area of the product that is available for heat flow, the temperature difference between the surface of the product, and the cooling medium (usually air or water), as well as the convection heat transfer coefficient. The convection heat transfer coefficient is dependent on the shape of the product, the thermophysical properties of the product, and the velocity with which the cooling medium (usually air or water) moves over the product.

There are two major factors in convection cooling that can be manipulated to remove heat from a carcass (Briggs, 1999). One factor is the convection heat transfer coefficient. Increasing the speed at which the cooling medium passes over the product can optimize heat removal. For example, incorporation of high-speed fans in a carcass cooler will increase heat removal by increasing the convection heat transfer coefficient. Another way to remove heat quickly is to increase the difference in temperature between the product and the cooling medium. The greater the difference in temperature between the product and the cooling medium, the faster the product can be cooled.

Another mechanism of heat transfer is conduction. Conduction transfers heat from a solid via vibrating molecules. With this mechanism, there is no physical movement of fluid or air. An example of this would be cooling a product by placing it in direct contact with ice. Physical contact between the product and the source of refrigeration will extract heat by conduction. Heat is transferred via a temperature gradient and is moved from a high temperature region to a low temperature region. Therefore, during the cooling process, hea tis conducted from the center of the product to the surface. The speed at which this is accomplished will impact the overall cooling rate.

Convection and conduction occur simultaneously while chilling pork carcasses. Heat is transferred from the center of the product to the surface by conduction. During convection cooling, heat is transferred from the surface of the product to a cooling medium that passes over the product. Convection can be manipulated to increase the rate of heat transfer by increasing the speed at which the cooling medium passes over the product and by lowering the temperature of the cooling medium.

Chilling Methods

There are three types of chilling systems commonly used in commercial practices including conventional, spray, and blast/accelerated chilling systems. Less common forms of chilling include cryogenic chilling which utilizes liquid nitrogen and brine chilling. Many conventional chilling systems use temperatures near 34°F (1°C) with an air velocity of 1.5 to 3 feet/second for 24 hours. Spray chilling uses cold water [34°F to 41°F (1°C to 5°C)] that is periodically sprayed on the carcasses (for example, showering carcasses with cold water every 15 minutes for 60 seconds) combined with an air velocity of 1.5 to 3 feet/second for up to 10 hours. Conventional chilling usually follows spray chilling. Blast or accelerated chilling uses temperatures anywhere from -4°F to -40°F (-20°C to -40°C) often with an air velocity of 10 to 16 feet/second for 1 to 3 hours. This can either be followed by conventional or spray chilling systems. Among systems that are traditionally used in commercial settings, blast chilling typically provides the fastest rate of temperature decline in loins and hams. Spray chilling also lowers the temperature of the carcasses more quickly than does conventional chilling, but not as quickly as blast chilling. Cryogenic chilling systems lower the temperature of the loin in the shortest amount of time. Cryogenic chilling is done by dipping carcasses in liquid nitrogen at a temperature of -321°F (-196°C) for 1 to 3 minutes. The carcasses are further chilled by conventional systems. This system has been primarily used in research settings and is not currently feasible for use in most commercial plants. Brine chilling is similar to spray chilling with the exception that brine is sprayed onto the carcasses in order to chill them.

pH and Temperature Decline

Chilling can reduce the adverse effects of mild forms of PSE because as temperature decline is accelerated, rate of pH decline will decrease. Therefore, efficient chilling systems should aid in reducing the occurrence of PSE. In practice, results can vary in terms of the effect chilling system has on pH decline (Murray, 1999). Cryogenic chilling, the system with the most rapid temperature decline also results in the least rapid rate of pH decline. Jones et. al. (1991) found loin temperatures were significantly reduced at 2 and 6 hours post mortem if liquid nitrogen was utilized, the largest effect was at 2 hours postmortem. Furthermore, carcass sides that were dipped in liquid nitrogen had higher pH values at 6 hours postmortem when compared to conventionally chilled sides, although there were no differences in pH at 45 minutes or 24 hours postmortem (Jones etal., 1991). In the same study, although liquid nitrogen chilling was shown to reduce the rate of pH decline in halothane negative pigs, it was not shown to significantly reduce pH decline in halothane positive pigs (Jones et al., 1991).

Among the systems that are more commonly used in U.S. plants, conventional and spray chilling systems result in a faster pH decline when compared to blast chilling (Dransfield et al., 1991; Jones et al., 1993; Long and Tarrant,1990; Milligan et al., 1998). Jones et al. (1993) showed loin temperature fell below 10°C within three hours of blast chilling. McFarlane and Unruh (1996) showed blast chilling decreased loin temperatures at two hours postmortem but did not observe decreased loin temperatures at 45 minutes or 24 hours postmortem. Furthermore, McFarlane (1996) found no difference in forty-five minute or two-hour pH values for carcasses chilled by conventional or blast chilling, but showed higher twenty-four hour pH values for blast chilled carcasses. Although Dransfield et al., (1991) found blast chilling to slow pH decline, there was no effect found on ultimate pH when rapid chilling was compared to conventional chilling.

Additional methods of reducing temperature and the rate of pH decline in carcasses include hot-trimming or skinning of carcasses and handling practices of the pigs prior to slaughter. Hot-trimming or skinning of carcasses prior to chilling allows for a more rapid chill of the carcass (Milligan et al., 1998) thus reducing the rate of pH decline. Meade and Miller (1990) showed that trimmed carcasses had a more rapid temperature decline for the first three hours; however, there was no difference found in 24-hour ham temperatures. A study analyzing the effects of showering pigs prior to slaughter to lower body temperature showed that showering did in fact lower the loin muscle temperature, but showering alone did not reduce rate of pH decline. However, in combination with rapid chill, live animal showering was effective in reducing the rate of pH decline (Long and Tarrant, 1990).

What may be more important than the actual rate of pH decline is the relationship between the temperature and pH during that pH fall. Most of the pH decrease in the loin occurs above 68°F (20°C) for conventional chilling systems and spray chilling systems. During blast chilling, most of the decrease in pH occurs above 50°F (10°C). The biggest decrease in pH during cryogenic chilling occurs below 50°C (10°F).

Carcass shrink

The amount of carcass shrink is affected by chilling method. The application of spray and the severity of the chill process have been shown to reduce the amount of carcass shrink. Of the two factors, spray seems to have a greater impact than does decreased chilling temperature. Spray chilling appears to minimize carcass shrink primarily by increasing the weight of skin and subcutaneous fat (Jones et al.,1988). Combining low chill temperatures with spray chilling systems appears to have the greatest effect on reducing carcass shrink (Murray, 1999). Blast chilling at -40°F (-40°C) followed by spray chill, has been shown to essentially eliminate carcass shrink in some research trials (Murray, 1999). Other trials have shown that spray chilling at conventional temperatures and blast chilling followed by spray chilling can reduce the amount of shrink (Jones et al., 1993; Longand Tarrant, 1990). Jones et al. (1993) showed that conventionally spray chilling carcasses was just as effective as blast chilling at –4°F (20°C) followed by spray chilling at reducing shrink. Jones et al. (1993) also found that blast chilling at –40°F (–40°C) followed by spray chilling reduced carcass shrink. Furthermore, liquid nitrogen chilling has been effective in reducing carcass shrink of “normal” pork carcasses as well as carcasses that were either halothane positive or halothane negative (Jones et al., 1991).

Color and Tenderness

Spray chilling appears to have little effect on color (Jones et al.,1988; Long and Tarrant, 1990; Murray, 1999). Some studies have shown however, that blast chilling can affect loin color, making the loins darker the longer they are held in the blast system (Jones et al., 1993; Jones et al., 1990; Jones et al., 1987; Milligan et al., 1998). Unlike those studies, a study by Crenwelge et al. (1984a) showed no difference in loin muscle color when comparing blast chilling, conventional chilling and brine chilling. However, ham muscle color was intensified for blast chilling and brine chilling when compared to conventional chilling methods. Research conducted by Jones et al. (1991) showed no difference in color when comparing liquid nitrogen to conventional chilling systems.

Jones et al. (1991) showed an increase in tenderness of loins chilled with liquid nitrogen after one minute, yet shear force values for those carcasses that were dipped in liquid nitrogen for three minutes were similar to the conventionally chilled carcasses. The same study showed no difference in shear values when comparing halothane positive and halothane negative carcasses that were dipped in liquid nitrogen (Jones et al.,1991). Although blast chilling for long periods of time (3 hours) can decrease tenderness (Jeremiah et al., 1992; Jones et al., 1993), several studies found no difference in shear force values when comparing rapidly chilled carcasses to those conventionally chilled (Crenwelge et al.,1984b; Dransfield et al., 1991; McFarlane and Unruh, 1996).

Drip Loss

Spray chilling and cryogenic chilling appear to have little effect on the drip loss of loins (Dransfield et al., 1991; Long and Tarrant, 1990). Blast chilling may slightly reduce drip loss of loins, although the magnitude of the improvement is often not as great as for other quality traits (Jeremiah et al., 1992; Murray,1999).

In summary, conventional and spray chill systems appear to take the longest time to decrease the temperature. Therefore, pH decline is most rapid with these chilling methods, leaving opportunity for PSE conditions to develop. Cryogenic chilling quickly drops the temperature and decreases rate of pH decline. Nonetheless, with this system, potential exists for product that is possibly less tender and its implementation is not currently practical. Blast chilling fits inbetween these two extremes and may offer the best opportunity to produce product with acceptable quality.

Summary

In summary, chilling is done to remove heat from the carcass. The removal of heat has a great impact on the quality of the meat product. If heat is not removed quickly enough and the pH declines rapidly, the potential to produce PSE product exists. This PSE product has a lower water holding capacity compared to product with a normal temperature and pH decline. However, if the temperature declines too quickly, the potential for development of a tougher product exists. Furthermore, chilling the product can retard microbial growth of spoilage organisms and pathogens. There are various types of chilling systems. Each of these systems has the potential to exert a different effect on pork quality. The best system to chill carcasses would be the one that minimizes the rate of pH decline and maximizes the rate of temperature decline without compromising pork quality.

References

Briggs, J. 1999. Introduction to heat transfer. National Pork Producers Council Chilling Workshop. National Pork Producers Council, Des Moines, IA

Crenwelge, D.D., R.N. Terrell, T.R. Duston, G.C. Smith and Z.L. Carpenter. 984a. Effect of chilling method and electrical stimulation on pork quality. J. Anim. Sci. 59:697-704.

Crenwelge, D.D., R.N. Terrell, T.R. Dutson, G.C. Smith and Z.L. Carpenter. 1984b. Effects of time postmortem of electrical stimulation and postmortem chilling methods on pork quality and palatability traits. J. Food Sci. 49:294-295.

Dransfield, E., M.J. Ledwith and A.A. Taylor. 1991. Effect of electrical stimulation, hip suspension and ageing on quality of chilled pig meat. Meat Sci. 29:129-139.

Honikel, K. 1999. Influence of Chilling of Pork Carcasses on Physical Quality Traits. National Pork Producers Council Chilling Workshop. National Pork Producers Council, Des Moines, IA.

Honikel, K.O. 1990. Chilled Foods: The State of the Art. T.R. Cormley (ed.). Elsevier Applied Science. Essex, England.pp.122.

Jeremiah, L.E., S.D.M. Jones, B. Kruger, A.K.W. Tong and R. Gibson. 1992. The effects of gender and blast-chilling time and temperature on cooking properties and palatability of pork longissimus muscle. Can. J. Anim. Sci. 72:501-506.

Jones, S.D.M., L.E. Jeremiah and W.M. Robertson. 1993. The effects of spray and blast-chilling on carcass shrinkage and pork muscle quality. Meat Sci. 34:351-362.

Jones, S.D.M., G.G. Greer, L.E. Jeremiah, A.C. Murray and W.M. Robertson. 1991. Cryogenic chilling of pork carcasses: effects on muscle quality, bacterial populations and palatability. Meat Sci. 29:1-16.

Jones, S.D.M., G.G. Greer, A.C. Murray and W.M. Robertson. 1990. Chilling method affects meat quality. NationalProvisioner. 202 (April 16) 9-10.

Jones, S.D.M., A.C. Murray and W.M. Robertson. 1988. The effects of spray chilling pork carcasses on the shrinkage and quality of pork. Can. Inst. Food Sci. Technol. J. 21:102-105.

Jones, S.D.M., A.K.W. Tong and A.C. Murray. 1987. Effects of blast chilling carcasses of different weight and fatness on the appearance of fresh pork. Can. J. Anim. Sci. 67:13-19.

Long, V.P. and P.V. Tarrant. 1990. The effect of pre-slaughter showering and post-slaughter rapid chilling on meat quality in intact pork sides. Meat Sci. 27:181-195.

McFarlane, B.J. and J.A. Unruh. 1996. Effects of blast chilling and post mortem calcium chloride injection on tenderness of pork longissimus muscle. J. Anim. Sci. 74:1842-1845.

Meade, M.K. and M.F. Miller. 1990. The use of rapid chilling to reduce pale, soft and exudative pork from highly stressed market hogs. J. Anim. Sci. 68: Supp. 1: 351.

Milligan, S.D., C.D. Ramsey, M.F. Miller, C.S. Kaster and L.D. Thompson. 1998. Resting of pigs and hot-fat trimming and accelerated chilling of carcasses to improve pork quality. J. Anim. Sci. 76:74-86.

Murray, A. 1999. Pork Chilling: Canadian Research Update. National Pork Producers Council Chilling Workshop. National Pork Producers Council, Des Moines, IA

Smulders, F. 1999. Controlling Microbial Growth and Survival on Pork, with Particular Reference to the effects ofRefrigeration. National Pork Producers Council Chilling Workshop. National Pork Producers Council, Des Moines, IA.

Time Postmortem Temperature

At death 39°C

1 hour postmortem 35-37°C

2 hours postmortem 30-32°C

3 hours postmortem 26-28°C

5 hours postmortem 22-24°C

6 hours postmortem 20°C

10 hours postmortem 12°C

20 hours postmortem 5-6°C

Figure 2. Optimal Chilling Rate of the Loin (Honikel, 1999)

Figure 1. Loin Temperature Decline